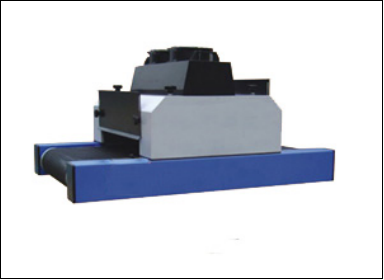

Scope of application

It is suitable for fast drying of solvent-based inks and drying of general moisture-containing items. Such as: paper prints, chemical products, glass, sheet, PVC, cloth, metal nameplates, etc.

Main parameters

| Machine model | TX-1100IR | Loading section length | 1500mm |

| Length of blanking section | 1000mm | IRheating section | 2000mm *5段 |

| Feed port height | 100mm | Conveyor width | 1100mm |

| Power | about 60KW | Heating method | Infrared lamp (glass) |

| Power supply | 380V | Total length | 12.5米 |

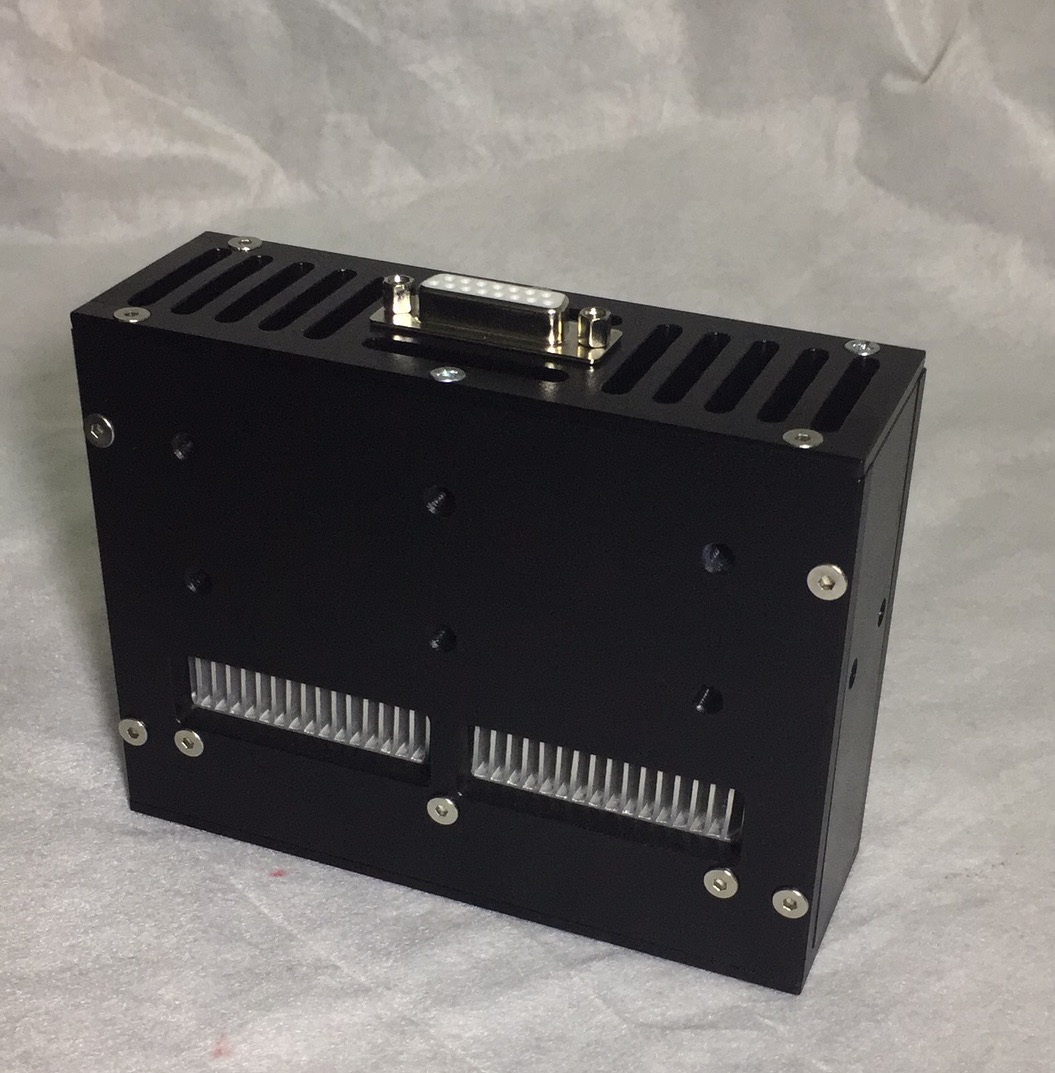

Main accessories

| No. | Part Name | Brand |

| 1 | Pneumatic Cylinder, Pneumatic Control Valve, Pneumatic Accessories | SMC |

| 2 | Bearing housing | THK |

| 3 | Circulation fan | Taiwan TECO |

| 4 | Transmission motor | Taiwan TECO |

| 5 | Reducer | Taiwan TECO |

| 6 | Inverter | Siemens |

| 7 | Circuit breakers, contactors, electronic overload protectors | Schneider |

| 8 | Intermediate relay | Schneider |

| 9 | Solid State Relay | Ohm |

| 10 | Temperature Control | Ohm |

| 11 | button | Schneider |

Production material

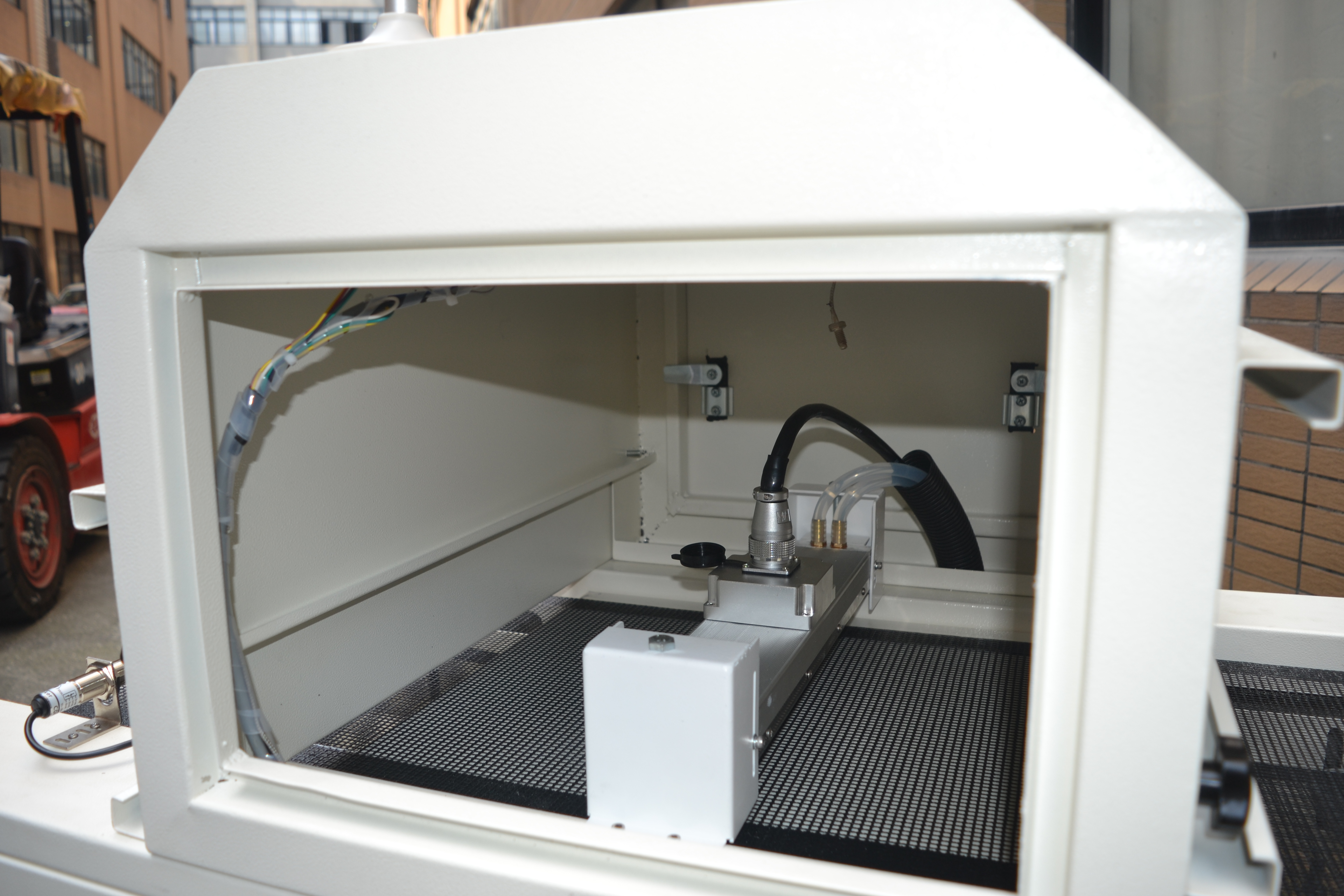

①Heat curing box:

Curing box: 80mm insulation board (filled with aluminum silicate wool, inner plate is 304 stainless steel plate, outer plate is 2mm cold-rolled plate)

Inner tank width: 1150mm outer width 1350

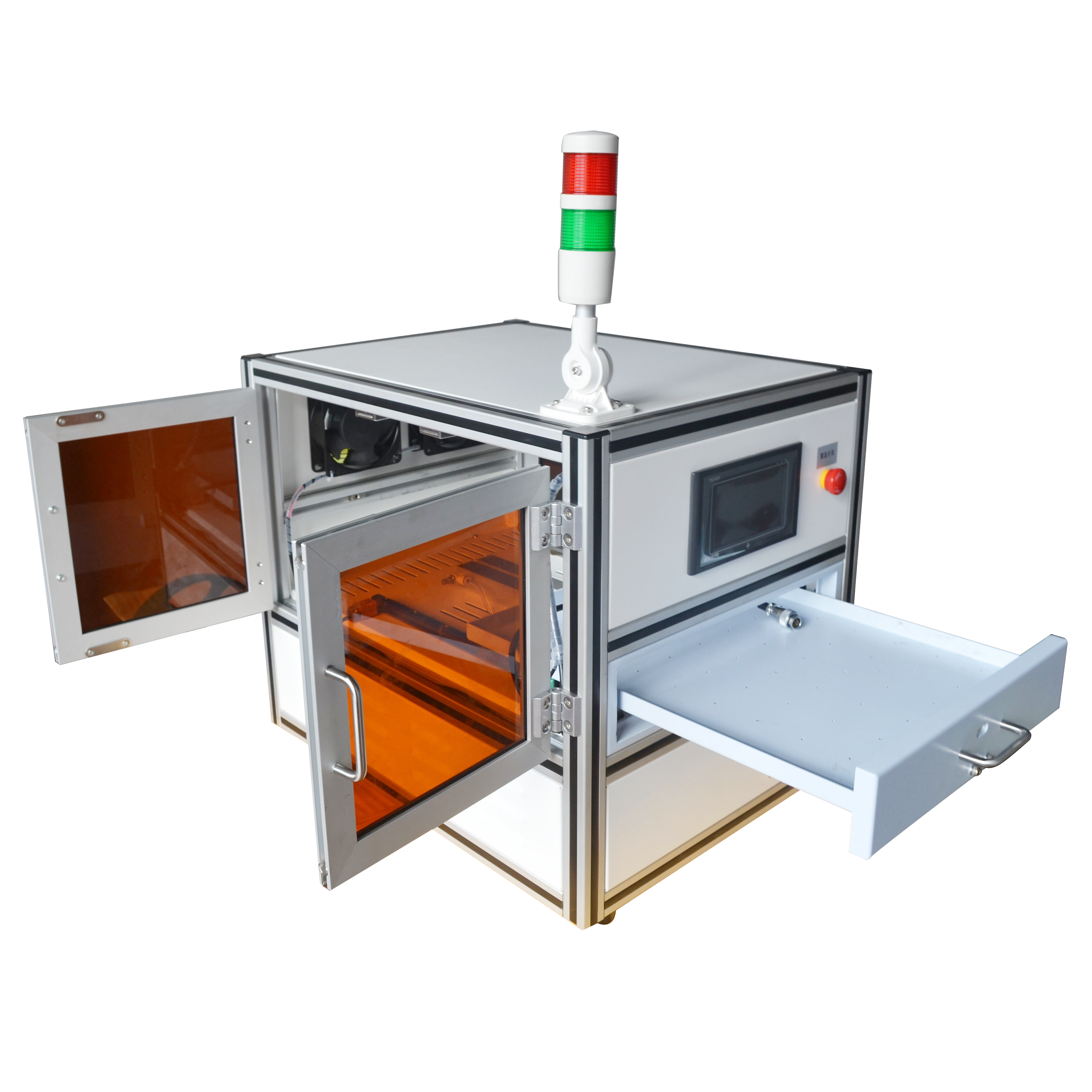

☆Heating light source: 380V 45 infrared heating tubes

Single heating length: 1100mm 1.2KW

Total heating power: 54 KW

The heating system is divided into 5 groups of control, temperature control and display temperature.

Heating temperature requirements: room temperature -180 degrees (adjustable)

Relative temperature difference: plus or minus 3-5 degrees (to ensure uniform heating temperature)

Temperature control accuracy: plus or minus 2 degrees

Circulating fans: 5 sets, power 0.45KW*5

Transmission system: speed range: 0-10m/min

The transmission network is: using high temperature resistant Teflon mesh belt, the transmission speed is stable, no impact, no noise

Features of this machine:

Our company adopts the latest foreign advanced technology, adopts high-performance infrared lamp tube and circulating hot air heating method to speed up

ink drying speed.

1. The heating area of the machine is 10 meters in total and has 5 heating sections.

2. Infrared + PID uninterruptible power supply + strong circulating air = high efficiency and energy saving.

3. The heating part of the machine is heated by infrared lamps, with large infrared energy and strong penetration rate, and the drying material can achieve the best drying effect.

4. The parts of the lamp tube are placed on the top of the inner cavity, and the installation port of the lamp tube is located on the side of the dryer, which is convenient for maintenance.

5. The drying system adopts a pneumatic side flip cover design, which is convenient for cleaning and maintenance.

6. Adopt frequency conversion speed regulation.

7. Contactors and air switches are made in China

8. The temperature control system of this machine is divided into 5 sections, each section controls the temperature separately, each section has a temperature control meter, the temperature control is expressed to the set temperature, and the heating lamp is controlled by constant temperature to ensure that the temperature in the box does not exceed the set temperature. temperature

9. When the temperature of the drying room is lower than the set temperature, the lamp tube heats up quickly, and when the temperature of the drying room is close to the set temperature, the lamp tube heats up slowly.

10. The terminals of the electric heating tube are protected by pressure-resistant porcelain, and the temperature-resistant wire protection tube is high-temperature resistant.

11. The circulating fan and exhaust fan use motors with high temperature resistance and high insulation level.

12. The whole machine adopts a split structure, which is convenient for inspection and maintenance.

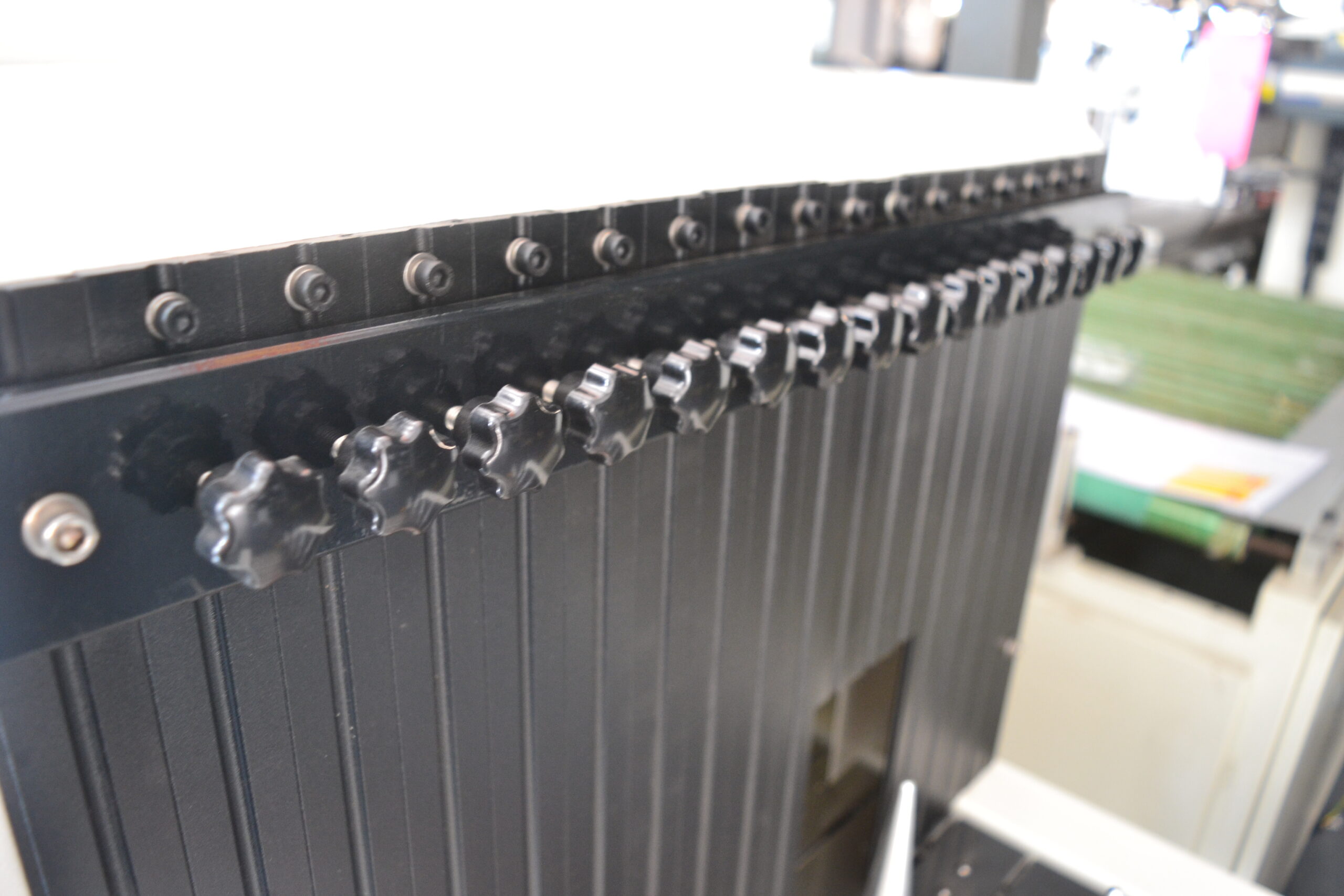

13. For the displacement of the conveyor belt, a fixed or pneumatic adjustment device is used to ensure that the mesh belt will never deviate, in order to achieve the purpose of the mesh belt not running!

14. Conveyor belt speed controller, with scale display, speed precision adjustment

15. The junction of the oven and the oven is fully sealed, and the positions of the lamps in the drying tunnel are evenly distributed

16. In the drying tunnel, the cables are made of high temperature resistant materials, and the joints must be wrapped with high temperature resistant materials

17. Using variable frequency motor.

18. In the drying tunnel, the temperature probe can adjust the length of the rod-shaped probe. The detection length is not less than 10CM

19. Because the length of the drying tunnel is too long, add hosting or brackets below the mesh belt of the drying tunnel. Prevent the mesh belt from falling

20. The color of Teflon mesh belt is black or brown.

21. Chassis color white or gray.