What is a flat screen printing machine?

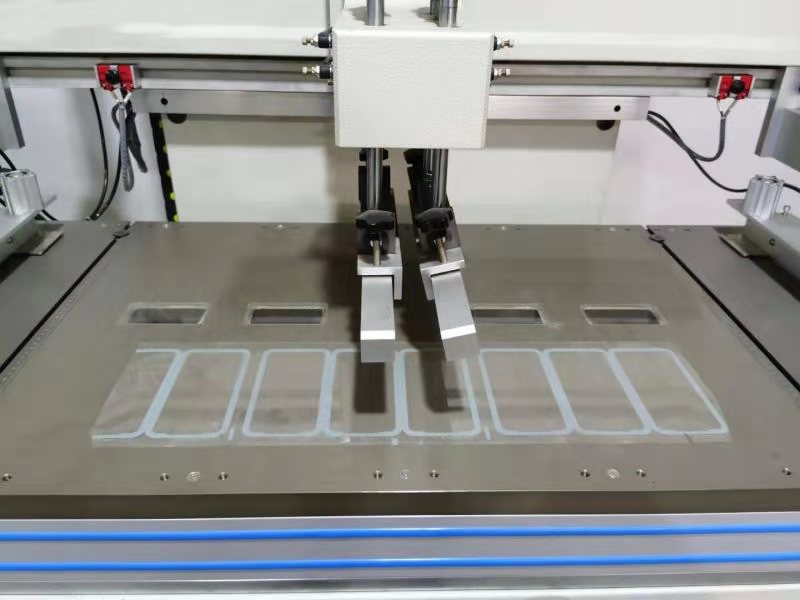

The full name is a flat screen printing machine. It is a screen printing machine that uses a flat screen plate to print on a flat substrate. When printing, the printing plate is fixed, and the squeegee plate is pressed against the printing plate. It moves horizontally and replaces the substrate through the ups and downs of the printing plate. It is a kind of screen printing machine that is used more.Flat screen printing machine is divided into automatic, semi-automatic, pneumatic, servo, manual flat screen printing machine.

work process

One of its working cycles is: feeding parts → positioning → setting plate → lowering to ink plate, raising ink plate back → scraping stroke → rising to ink plate → lowering ink plate → lifting plate → ink return stroke → releasing positioning → retracting pieces.

It is suitable for printing cigarettes, wine, medicine boxes and other frosted, ice flower boutiques and other series of packaging. High-precision four-color screen light box advertising, medium-sized posters, single/double-sided printed circuit boards, various metal plates, films, transfer stickers, stickers, various PVC, plastic books, glass and other screen printing products

Flat screen printing machine performance

1. The printing is driven by a frequency conversion motor, which is sensitive in action, uniform in speed, and adjustable in speed;

2. The vertical lift is driven by frequency conversion motor, frequency conversion speed regulation, the whole machine runs smoothly;

3. The four cylinders of the scraper and the ink return knife can be switched independently, and the printing pressure can be adjusted;

4. Vacuum adsorption to fix the printed parts;

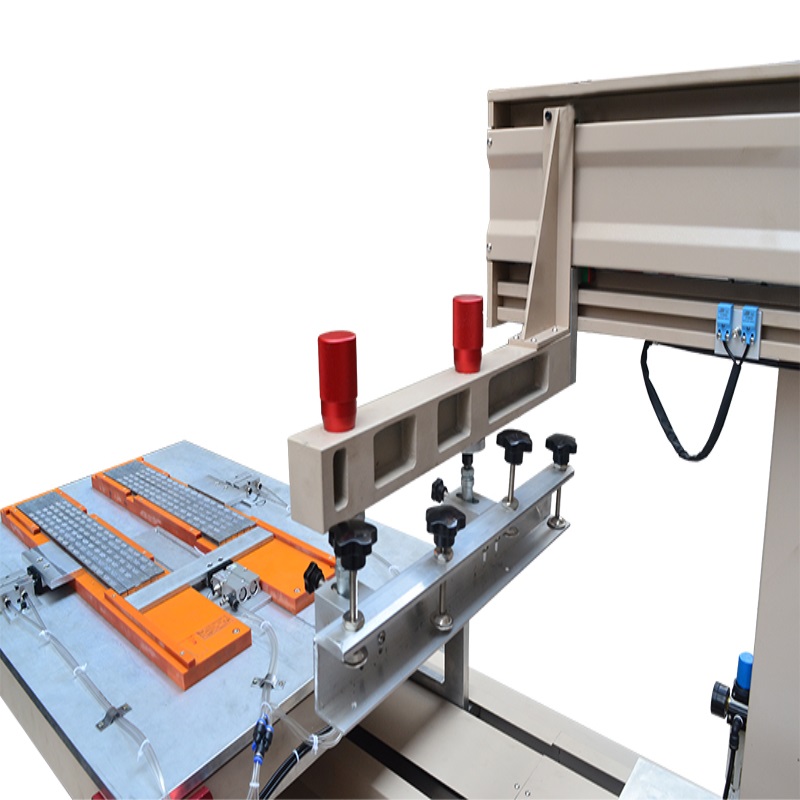

5. The worktable is equipped with front and rear, left and right fine-tuning devices, which makes the plate matching more accurate and convenient;

6. Equipped with a safety device to make the inclined arm stop at the upper position, with reliable safety;

7. Mechanical off-grid, off-grid speed is synchronized with printing to prevent sticking;

8. The front and rear screen clips are adjustable, and the minimum 400mm screen can be used, which greatly improves the application range of the screen

9. The electronic control unit is centrally controlled by microcomputer control, the operation of the whole machine is simpler and more flexible, and the maintenance is easy.