Automatic CCD Roll-to-Roll Flat Screen Printing Machine

Contact Us

Inquiry

Application:

It is suitable for screen printing of flat whole roll substrates, that is, roll materials. (Such as: PET, PVC, OPP and other transfer paper (film), non-inductive label, LED light bar, floor heating film, geothermal film, decal paper, FPC/PCB flexible circuit board, mobile phone buttons, 3M glue, membrane switch, conductive Screen printing of film, self-adhesive labels, stainless steel, aluminum foil, copper foil and other roll materials.)

Features:

- Automatic printing of roll material, repeatable color registration, fast printing speed, up to 1200~2200 prints per hour (depending on the product size), only one person is required to operate (saving labor and time).

- Equipped with automatic uniform speed rewinding oven, after printing, the rewinding is 0-60m to dry, which occupies a small area compared with the traditional tunnel oven (saving space cost).

- According to different industries, optional additional configuration (punching device, anti-static device, tearing film and laminating device, suction drum device).

Specifications:

| Parameters | 1. Printing table size: 500*700mm

2. Maximum printing area: 500*700mm 3. Maximum screen frame size: 800*1100mm 4. The maximum thickness of the screen frame: 30~45mm (special can be customized) 5. The fastest printing speed: 800-1500 P/H 6. Power specification: 3-phase, 380V, 50Hz 7. Air pressure: 5~6kg/cm2 PSI 8. Air consumption: 2.6L/cycle 9. CCD positioning accuracy: 0.02mm 10. Printing accuracy (non-material shrinkage and screen expansion): 0.05mm 11. The distance between the centers of the two CCDs: 330mm (adjustable range: horizontal ±100mm, vertical ±40mm) 12. Machine size: 2500*1150*1650mm 13. Machine weight: about 600KG |

| Configuration | 1.Linear guide rail: Taiwan Silver, both printing and up and down transmission adopt double guide rails

2.The upper and lower photoelectric of the screen frame: Japan Omron 3.Printing servo: Japanese Panasonic motor 4.Pulling servo: Japan Yaskawa Electric 5.CCD130 pixels: American ON Semiconductor 6.Photoelectric switch: Japan Omron 7.Bearing: Japan NSK 8.Cylinder solenoid valve: Taiwan Airtec |

Main performance

Feeder characteristics:

Automatic feeding, automatic elimination of static electricity;

The maximum discharge diameter is 600mm;

It adopts Japanese Panasonic inverter control, and the discharge speed is adjustable from 0-600r/n at a constant speed;

Adopt photoelectric control to discharge the material to avoid scratches on the surface of the material

Unwinding speed and time can be adjusted at will;

Equipped with automatic tearing film function;

Automatic shutdown without material;

Host features:

Using the touch screen man-machine interface to operate the button switch, PLC control, various functions and parameters can be set, and the operation is convenient;

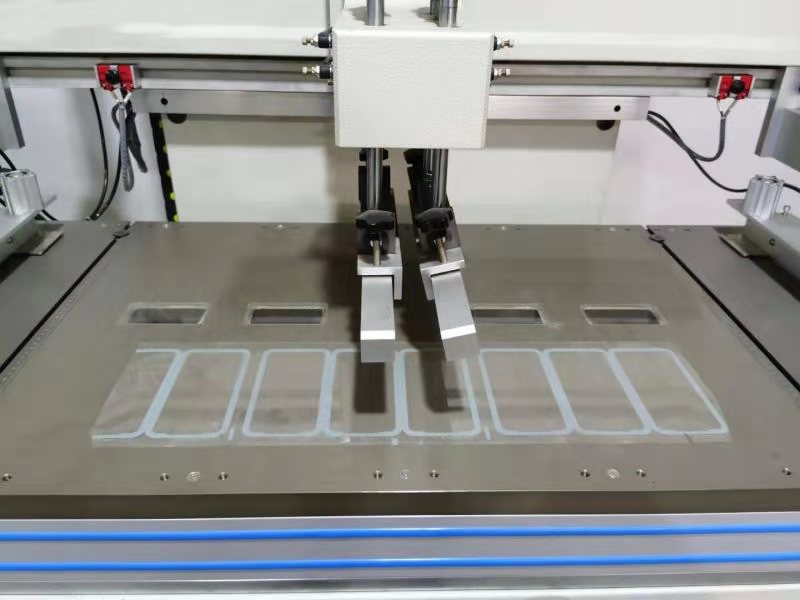

CCD automatic positioning and printing, can automatically adjust the field of view of the CCD according to the size of the material;

CCD automatically calculates the spatial position of the material and the screen based on the Mark point on the material, and instructs the motor to control the adjustment platform X, Y, θ to rotate and automatically position and print;

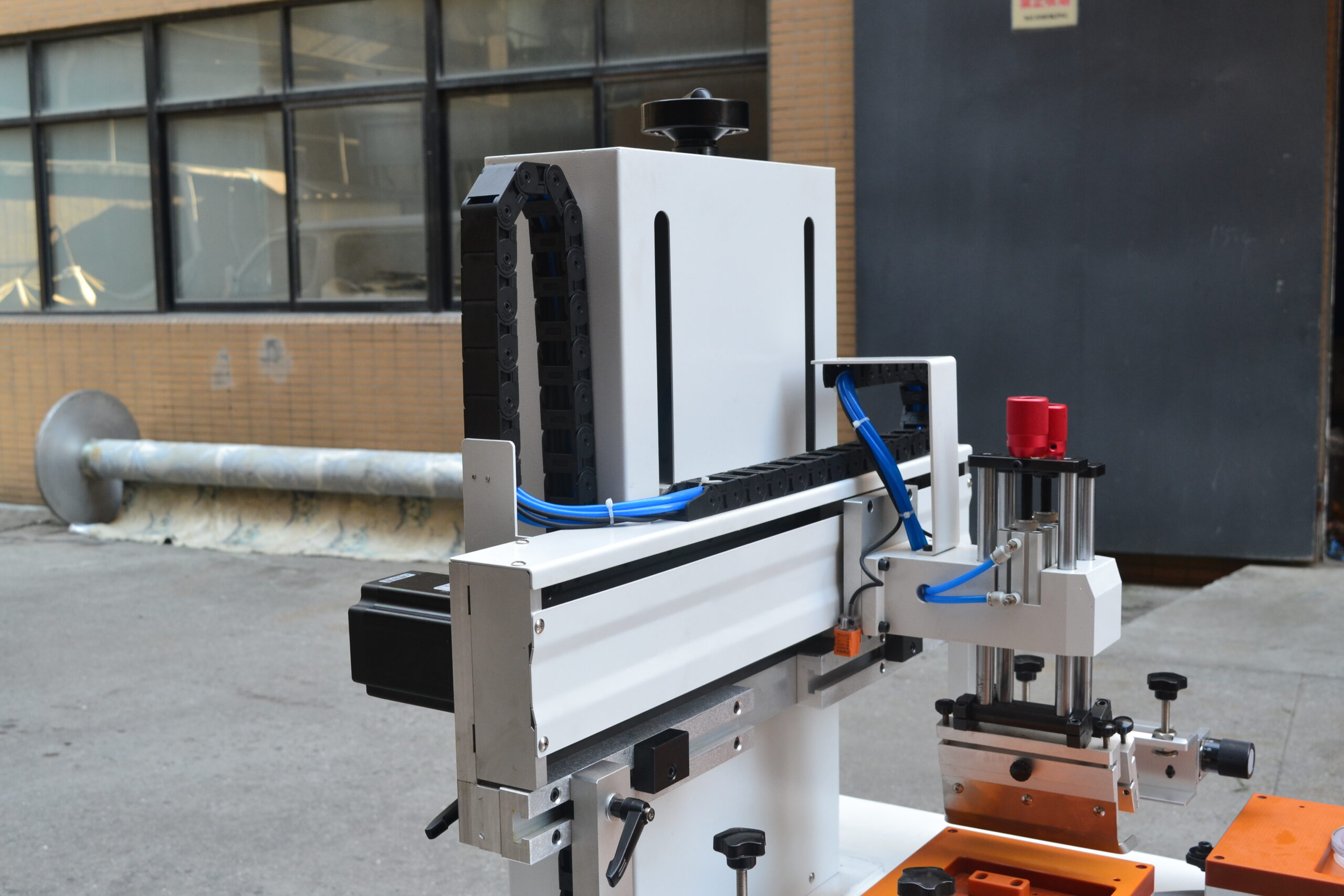

The brush adopts Panasonic servo motor, matched with linear guide rail, fast and stable, precise positioning;

It is convenient to set the screen position, printing pressure, squeegee speed, height of the plate frame, etc.;

The printing speed can be set at will, and the printing quantity can be calculated. When the set quantity is reached, it will automatically stop and give an alarm;

Automatically shut down and alarm when abnormal or no material occurs;

Printing adopts a cleaning roller to remove dust, which can remove dust from printed materials and improve product qualification rate;

The screen clamping frame adopts pneumatic automatic clamping design, which is easy to operate;

The printer is equipped with auxiliary product inspection work lights to facilitate the inspection of defective products;

The squeegee and the ink-returning knife can be adjusted separately, and the squeegee can be used on both sides to extend the service life;

Using CNC motor, printing and ink return speed can be set in sections at will.

Using numerical control motor, printing and ink return distance can be set freely.

The machine’s tension adopts suction design to avoid material scratches and keep the tension constant;

Using the automatic off-screen function, it can prevent the screen from sticking when printing a large area of background color, glue and circuit board silver paste;

The touch screen is used to control the lifting of the printing head, which is convenient for the maintenance, loading and unloading and cleaning of the screen and the scraper;

The machine body is equipped with movable rollers for easy transportation. A number of humanized designs are conducive to operation;

Safety pressure plate, photoelectric switch, emergency stop button, thorough safety protection;

Coil material running direction: the direction of the material running from the right to the left if the customer has no special requirements (also can be customized according to customer requirements);

Can be customized according to customer requirements to meet different requirements

Oven characteristics:

Circulating hot air drying, adjustable temperature, automatic winding;

The oven is equipped with a thermal insulation layer, which saves electricity, energy and environmental protection;

This machine occupies a small area, with 9 cycles of internal circulation, and a length of about 60 meters. It can achieve low-temperature drying to ensure that the printed material does not shrink and deform, which is more conducive to multi-color printing;

The oven is equipped with auxiliary product inspection work lights;

The machine body is equipped with movable rollers for easy transportation. A number of humanized designs are conducive to operation.

Introduction to the use interface of roll-to-roll CCD counter-precision printing machine

- Main interface: The main interface of the machine is clear, simple and powerful. The main interface of the machine contains all the functions required by the customer, and the customer can start the operation with one key in the main interface. Easy to use and simple to operate, you can use it proficiently with simple training:

- CCD position adjustment: CCD position adjustment can automatically adjust the field of view of the CCD according to the position of the Mark point on the customer’s material. The adjustment range of the CCD: 430mm (horizontal ±80mm, vertical ±40mm), only the Mark point on the customer’s material Within this range. Then you can automatically adjust the position of the MARK point:

- Alignment setting: The alignment setting includes the core parameter settings of the internal parameters of the machine. In the alignment setting, control options are given to adapt to various printing phenomena such as material shrinkage and screen expansion. Customers can choose according to product requirements Printing accuracy, the software provides 6 options for printing accuracy: including X error equalization, Y error equalization, +X direction as reference, -X direction as reference, +Y direction as reference, -Y direction as reference:

- Alignment compensation: Alignment compensation is used to detect poor printing during the automatic printing process. When the graphics and text of the material expand or the material shrinks during the printing process, employees can adjust the alignment compensation as required to ensure the printing accuracy of the material . Alignment compensation provides 6 automatic adjustment directions including +X, -X, +Y, -Y, clockwise and counterclockwise rotation.

- Other functions: The main interface of the software includes the total printing quantity and the printing time of a single piece. The customer can set the automatic alarm for the printing quantity in the main interface, and can also see all the printing steps of the printing process at the bottom of the main interface. The software displays PASS every time the printing is successful

TaoXing Company Introduction

Taoxing automatic screen printing machine video compilation

Service / FAQ

Guarantee

① We provide comprehensive one-stop services, customer training and satisfied after sales services.

② Online support, video technical support for troubleshooting manufacturing problems, engineers are available to service oversea as necessary.

③ Sold enjoy one year of free equipment warranty and lifetime technical support.

Guarantee for Delivery

Safety and fast logistic ensures the goods are delivered on the right time

1. Packing: Plywood Case for Each Machine

2. Payment terms: T/T (50% deposit to start the production, 50% paid before delivery)

3. Delivery date:60 business days after received the payment.

4. Departure of port: By sea from Shanghai or Ningbo

5. Delivery means: By sea by land

A: We are a professional manufacturing factory specialize in printing equipment with more than 20 years experience, committed to supplying our customer top quality and dedication to the constant improvements of quality, reliability, productivity and the competitiveness of our products and services.

A: Please send us an inquiry directly. We need to get specific details, such as material, size, color, thickness, quantity, etc.

A: Yes, we have a professional technique team, we could produce the machine depends on your requirements.

A: We accept TT/LC/PAYPAL/Western union, every payment term we can discuss.

A: All Taoxing products carry up to a full year warranty. Supply wearing parts with favorable price and long term after-sales service. We believe in total customer satisfaction, aside from our no-hassle guarantee.

Screen printing was a technique first used by the Chinese almost 2000 years ago. It is widely used at home and abroad. Chinese printing machine market has already become the focal point of the world have opened up. We have teams of experienced technical experts and professionals providing most professional and just-in-time technical consults and services, timely supply of spare parts in place.

If you are still confused how to start printing work, don’t worry, contact us and we will help you out!! No mater you are a green hand, we will train you up-to-date technology skills, and keep an eye on your business opportunities. Our friendly and professional team that is able to handle all your inquiries whenever you need.