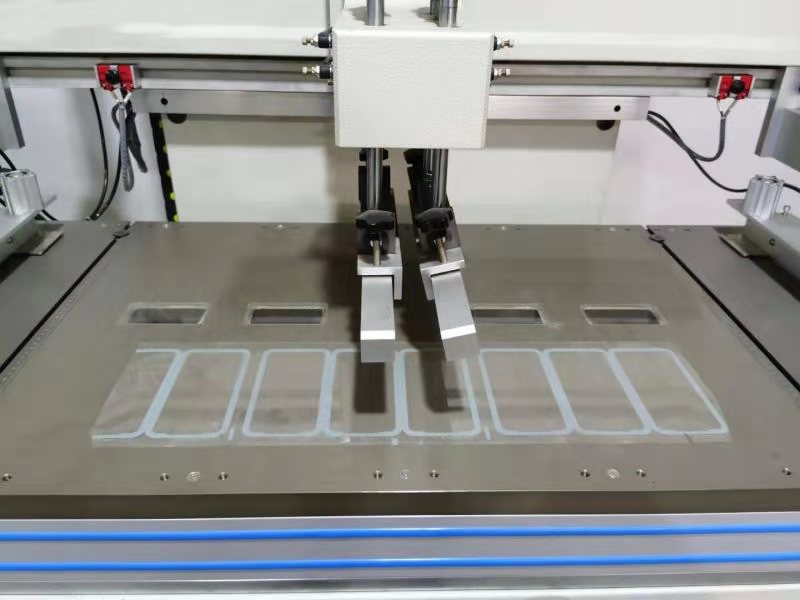

TX-CCD6090 sliding table CCD screen printing machine

Contact Us

Inquiry

1.Machine description:

Equipment features:

- The appearance and color of the whole equipment are unified and coordinated.

- The whole machine starts and stops with one key.

- Equipped with maintenance device to facilitate equipment cleaning and maintenance.

- The whole machine runs smoothly.

- With 4sets of CCD positioning printing, the positioning is accurate.

- The screen lift adopts vertical guide + servo drive, with high precision and accurate and stable positioning.

- The printing adopts high-precision silent guide rail + servo drive + synchronous off-grid structure, which runs smoothly and quickly.

- The printing/returning ink adopts high-precision cylinder, the printing pressure is digitally adjusted, and the printing pressure is constant and stable.

- Equipped with static elimination device to effectively avoid secondary pollution of printed parts.

- The digital man-machine interface of the whole machine is simple and convenient to operate.

2. The overall indication of the equipment:

3.Operate instruction

Manually feed the product into the positioning table ,

CCD image positioning (including 4 groups of CCDs),

After positioning, the table inhales and the product is fixed on the platform,

The table runs to the position of the printing press, starts printing,

After the printing is finished , the table returns to the CCD alignment position, the suction is cut off, manually discharge the product.

4.Technical performance parameters

Machine function 1、 Manually feeding , CCD positioning 2、Printing part: sliding table with CCD vertical positioning+ servo motor

Printing size Max :600 x900mm Min:100×350mm Machine size L3600 × W1350 × H1850 mm Voltage Single phase 220V 50HZ Pow(V/KW) 8KW Air source/Consumption 5-7kg/cm2、3 L/ Machine weight 1500kg Application It is suitable for many fields of screen printing, such as film circuits, nameplate buttons, precision electronics, plastics industry, ceramics industry, lens windows, EL (EL), liquid crystal display (LCD) and other industries. screen printing. Parameter 1、Max printing size :600~900mm; 2、Min printing size :100~350mm; 3、Table size :700*1100mm(High-precision grinding platform, the table is hard anodized);

3.Vacuum size:600*900mm; 5、Max frame size :1100*1600mm;

6、Frame height:30~50mm;

7、 sliding table speed :500-800mm/s;

8、position accuracy:±0.01mm;

9、working height:900±30mm;

10、Table vacuum hole size :30×30,diameter¢1.2mm; 11、printing thickness:0.1~50mm;

12. Table flatness:300×300mm±0.05mm; 13、screen distance accuracy:±0.05mm;

14、Printing accuracy :+-0.01mm; 15、printing table micro adjusting :X-axis±5mm,Y-axis±5mm; 16、printing speed (mm/sec):0~500mm adjustable 17、printing pressure (Kgf/cm2):0.4~5.0;

18、Scraper angle adjusting:0~30°;

19、 max production capacity:>= 400pcs/hour

20.Lifting repeating positioning accuracy、(mm):±0.01mm;21、position way: manually or CCD

22、repeating printing accuracy(mm):≦ ±0.05mm;

23、Parallelism between screen frame and table :<0.1mm;

24、Stencil rise height:300mm;

Advantage 1、CCD capturing arrange :X:330~900 Y:100~600mm , accuracy: 0.01mm,1300000 pixel 2、ITO Mark/ different shape Mark capturing, positioning capturing tome ≦ 1s;

3、 4 pcs CCD lens

4、There are protective devices to prevent displacement caused by personnel impact;

3. PLC control reserves 10% of the interface;

6. The entire machine is protected by software;

7. All electrical components have been specially tested to achieve hardware protection;

8. The feeding port is equipped with a static elimination device;

9. Printing/returning ink pressure control: numerical control setting, automatic constant pressure;

10. Different colors are used for trachea for different purposes: white trachea for vacuum; black trachea for air pressure;

11. Appearance color of the machine: the default computer white paint, or the color specified by the customer;

5, the main component brands

No Item Brand Marks 1 Programmable Controller PLC Taida 2 Photoelectric switch Matsushita 3 Servo motor + drive Taida /Hechuan 4 Linear Guides Shangyin 5 electromagnetic valve SMC/Yadeke 6 Pressure Switch SMC 7 Cylinder SMC/Yadeke 8 Low voltage electrical appliances Chint/OMRON/Schneider 六:Tool list

Tool

List

1 hexagonal wrench 1set 2 adjustable wrench 1ps 3 scraper clip 4sets Aluminum 4 trachea 1 pc( 5 meters) 5 Tool box 1pc 6 manual 1

TaoXing Company Introduction

Taoxing automatic screen printing machine video compilation

Service / FAQ

Guarantee

① We provide comprehensive one-stop services, customer training and satisfied after sales services.

② Online support, video technical support for troubleshooting manufacturing problems, engineers are available to service oversea as necessary.

③ Sold enjoy one year of free equipment warranty and lifetime technical support.

Guarantee for Delivery

Safety and fast logistic ensures the goods are delivered on the right time

1. Packing: Plywood Case for Each Machine

2. Payment terms: T/T (50% deposit to start the production, 50% paid before delivery)

3. Delivery date:60 business days after received the payment.

4. Departure of port: By sea from Shanghai or Ningbo

5. Delivery means: By sea by land

A: We are a professional manufacturing factory specialize in printing equipment with more than 20 years experience, committed to supplying our customer top quality and dedication to the constant improvements of quality, reliability, productivity and the competitiveness of our products and services.

A: Please send us an inquiry directly. We need to get specific details, such as material, size, color, thickness, quantity, etc.

A: Yes, we have a professional technique team, we could produce the machine depends on your requirements.

A: We accept TT/LC/PAYPAL/Western union, every payment term we can discuss.

A: All Taoxing products carry up to a full year warranty. Supply wearing parts with favorable price and long term after-sales service. We believe in total customer satisfaction, aside from our no-hassle guarantee.

Screen printing was a technique first used by the Chinese almost 2000 years ago. It is widely used at home and abroad. Chinese printing machine market has already become the focal point of the world have opened up. We have teams of experienced technical experts and professionals providing most professional and just-in-time technical consults and services, timely supply of spare parts in place.

If you are still confused how to start printing work, don’t worry, contact us and we will help you out!! No mater you are a green hand, we will train you up-to-date technology skills, and keep an eye on your business opportunities. Our friendly and professional team that is able to handle all your inquiries whenever you need.