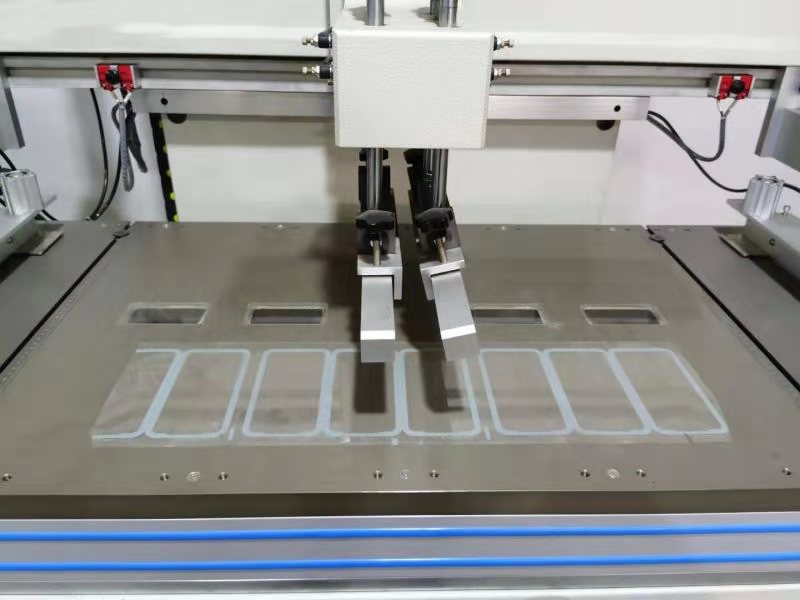

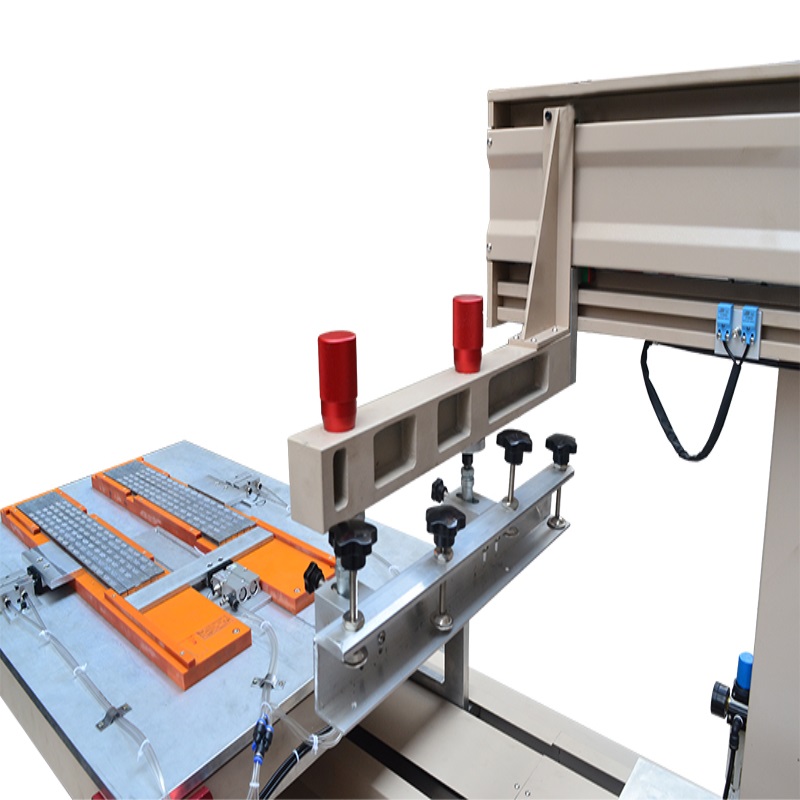

TX-YKPZ-5070 Automatic sheet screen printing machine

Contact Us

Inquiry

Application

This auto screen printing machine is widely used for adhesive paper, Ceramic decal paper, membrane switch, heat transfer film, transfer paper, and also suit for the high precision printing on any other paper card,thin metal sheet,PVC.

Parameter

| Max Printing size | 500X700mm | Table size | 700X900mm | |

| Vacuum Size | 600X800mm | Table to Ground Height | 1000mm | |

| Max frame szie | 900X1200mm | Frame thickness | 30-45mm | |

| Printing accuracy | ±0.10mm | Multiple printing accuracy | ±0.10mm | |

| Table Leveling accuracy | ±0.10 | Fine tuning accuracy | ±0.05mm | |

| Table Material | Stainless steel or hard alumina | Suction hole diameter | 1.2mm | |

| Printing & table parallelism | ±0.10 | Frame horizontal &vertical accuracy | ±0.10mm | |

| Product Thickness | 15mm | Frame rise height | 100mm | |

| Print Speed | 50-200mm/s | Printing stroke | 100-1000mm | |

| Printing direction | Right to left | Squeegee/ink knife distance | 60mm | |

| Squeegee/ink knife

Up &down stroke |

25mm | Squeegee/ink knife

regulation angle |

0-45° | |

| Squeegee/ink knife

Stroke adjustment |

Screw adjustment | Printing Move | Servo motor | |

| Squeegee/ink knife

Pressure control |

Pneumatic + mechanical | Frame Up& Down | Electric motor | |

| Frame cantilever fixing | screw | Frame fixing | Pneumatic + mechanical | |

| Frame parallelism adjustment | Screw adjustment | Positioning | Mechanical positioning | |

| Frame max rise height | 50mm | Frame Install | Front to back | |

| Control box location | Hanger type movable | Air consumption | Emergency stop switch | |

| Frame max rise height | Emergency stop switch | Power | 7L/min | |

| Voltage | 380V | Size | 6.5KW | |

| Weight | 1400KG | |||

1.The lift of the platform adopts frequency conversion, and the left and right movement of the printing head use servo electric drive

1、Print head adopts Inverter motor, the left and right movements of adopt servo motor, and the material positioning adopts CCD optical lens + Movable platform +industrial computer to ensure precise positioning.

2、Adopt the pneumatic control system for printing blade rotates, to achieve the anti-dripping effect, and the structure is compact, convenient and practical.

3、Manual/Semi-auto/Full Auto Model can be set,Printing Time adopt digital control

4、The independently designed system for head lifting device, squeegee/returning knife to make frame loading&unloading and cleaning more convenient.

5、The Frame is fixed by pneumatically/mechanically , and distance can be adjusted. Also the X and Y axes are independently adjusted.

6、Discharge and reclaim material controlled by Servo motor , which will run stable and the positioning is accurate.

7、Optional with static elimination and dust removal device, easy to operate and more efficient.

8、Adopt Large-size LCD display , easy operate.

9、Can be connect with the Powder coating machine, UV curing machine or IR drying tunnel to make the printing full-automatic. The design as follow

List show

| TX-YKPZ-5070 List show | |||

| Name | Specification | Brand | Place of origin |

| PLC | FX5U-80MT/ES | Mitsubishi | Japan |

| Touch screen | MT8071IP | Weinview | Taiwan |

| Sixteen-bit relay | Y448 | Shenglan | shenzhen |

| Eight-bit relay | Y412 | Shenglan | Shenzhen |

| Common section terminal | T075 | Shenglan | Shenzhen |

| Common section terminal | T078 | Shenglan | Shenzhen |

| Air switch | 3P32A | Zhengtai | Zhejiang |

| Air switch | 1P6A | Zhengtai | Zhejiang |

| Phase break and phase sequence protection relay | XJ3-G | Zhengtai | Zhejiang |

| A.c.contactor | C1*2-2510 | Zhengtai | Zhejiang |

| A.c.contactor | LG/0910 | Zhengtai | Zhejiang |

| Solenoid vale | YSVM220-4EI–5G-02 | YSC | Korea |

| Switching power supply | LRS-100-24 | Meanwell | Taiwan |

| Frequency converter | 220V 0.75KW | Yuanxin | Shenzhen |

| Frequency converter | 220V 1.5 KW | Yuanxin | shenzhen |

Machine maintenance

① Clean the sundries on the machine and wipe it clean before going to work.The guide rail, guide column, bearing and other moving parts should be lubricated regularly.

② The work piece table is the key part which affects the printing quality, prevents the hard object to hit, when printing, cannot turn the ink.The water and other organic solvents drip onto the work surface.

③ Electric control panel and keys to prevent direct or indirect contact with water, water and other solvents caused by damage.

④ Frame paint is to keep the machine rust, to prevent days of water, water and other solvents directly or indirectly contact damage.

⑤ The sewage and dirt in the oil mist assembly should be discharged in time.Prevent feeding into pneumatic components, affecting normal operation, and regularly clean the cup body, add peng 2 lubricating oil in the oil cup of oil mist assembler.

⑥ When adjusting the limit valve, the tight nut must be unscrewed before hand adjustment.Handle screw on the machine is used for positioning, after firm positioning, no need to tighten it too hard.

⑦ After work, turn off the power/air source, clean the screen, and keep it properly.

Distribution list

| No | Tool name | Spe | Uni | Qyt | Note |

| 1 | Power line | standard | Pc | 1 | |

| 2 | Foot switch | standard | Pc | 1 | |

| 3 | Cross screwdriver | standard | Pc | 1 | |

| 4 | Active wrench | standard | Pc | 1 | |

| 5 | Hex key | standard | Pc | 1 | |

| 6 | Tool cabinet | standard | Pc | 1 | |

| 7 | Operating instruction | Pc | 1 |

TaoXing Company Introduction

Taoxing automatic screen printing machine video compilation

Service / FAQ

Guarantee

① We provide comprehensive one-stop services, customer training and satisfied after sales services.

② Online support, video technical support for troubleshooting manufacturing problems, engineers are available to service oversea as necessary.

③ Sold enjoy one year of free equipment warranty and lifetime technical support.

Guarantee for Delivery

Safety and fast logistic ensures the goods are delivered on the right time

1. Packing: Plywood Case for Each Machine

2. Payment terms: T/T (50% deposit to start the production, 50% paid before delivery)

3. Delivery date:60 business days after received the payment.

4. Departure of port: By sea from Shanghai or Ningbo

5. Delivery means: By sea by land

A: We are a professional manufacturing factory specialize in printing equipment with more than 20 years experience, committed to supplying our customer top quality and dedication to the constant improvements of quality, reliability, productivity and the competitiveness of our products and services.

A: Please send us an inquiry directly. We need to get specific details, such as material, size, color, thickness, quantity, etc.

A: Yes, we have a professional technique team, we could produce the machine depends on your requirements.

A: We accept TT/LC/PAYPAL/Western union, every payment term we can discuss.

A: All Taoxing products carry up to a full year warranty. Supply wearing parts with favorable price and long term after-sales service. We believe in total customer satisfaction, aside from our no-hassle guarantee.

Screen printing was a technique first used by the Chinese almost 2000 years ago. It is widely used at home and abroad. Chinese printing machine market has already become the focal point of the world have opened up. We have teams of experienced technical experts and professionals providing most professional and just-in-time technical consults and services, timely supply of spare parts in place.

If you are still confused how to start printing work, don’t worry, contact us and we will help you out!! No mater you are a green hand, we will train you up-to-date technology skills, and keep an eye on your business opportunities. Our friendly and professional team that is able to handle all your inquiries whenever you need.