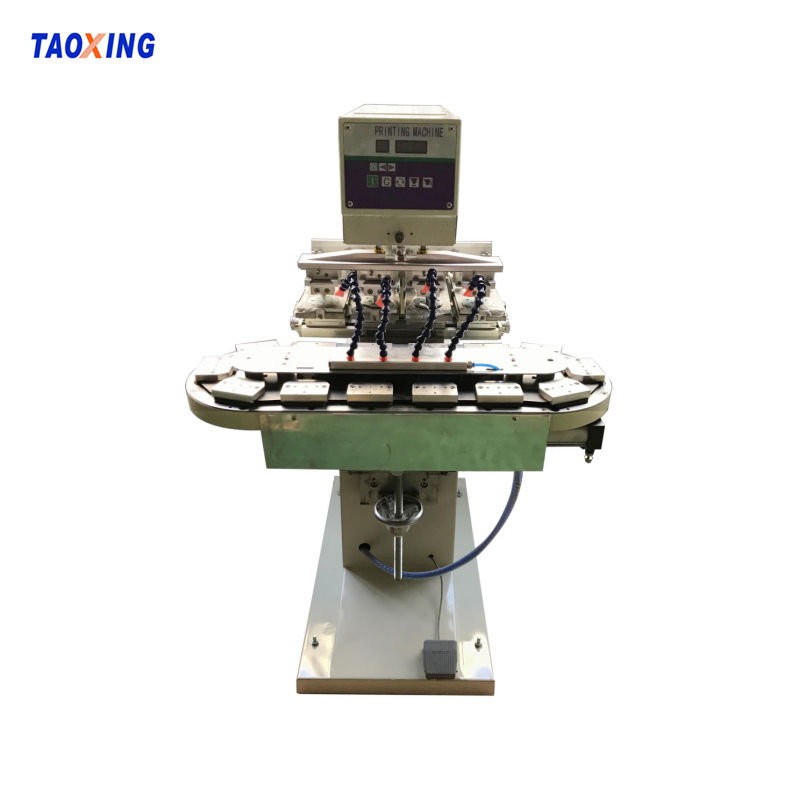

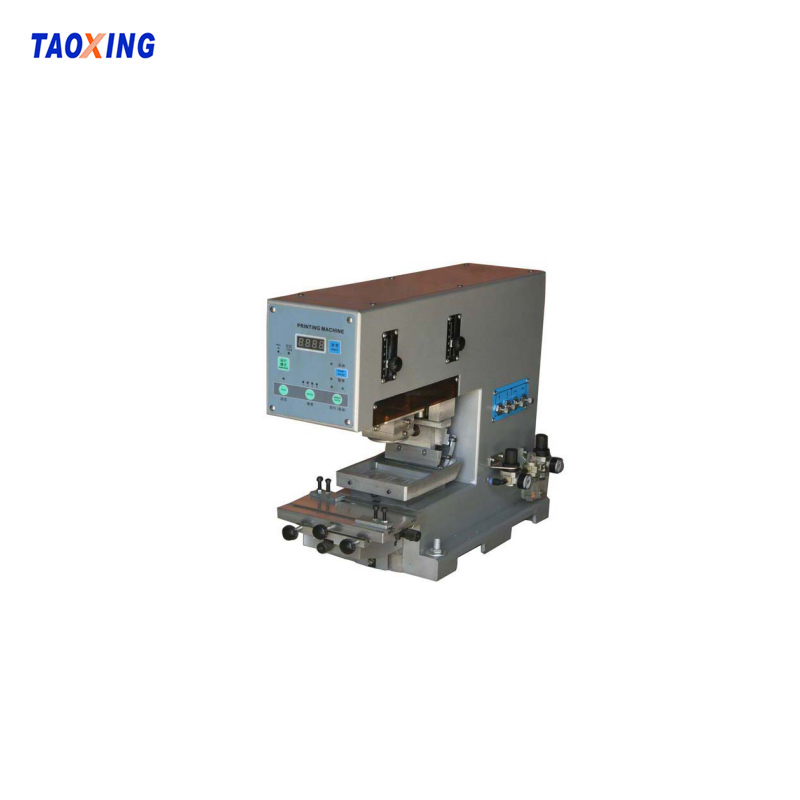

TXZ4-225-90 Four-color rotary pad printing machine

Contact Us

Inquiry

Scope of application

It is suitable for precision printing of flat, curved and irregular surface products with small printing area of metal, glass, ceramics, plastic, wood, leather and other materials.

main parameters

| machine type | TXZ4–225-90 | Ink loading method | oil cup |

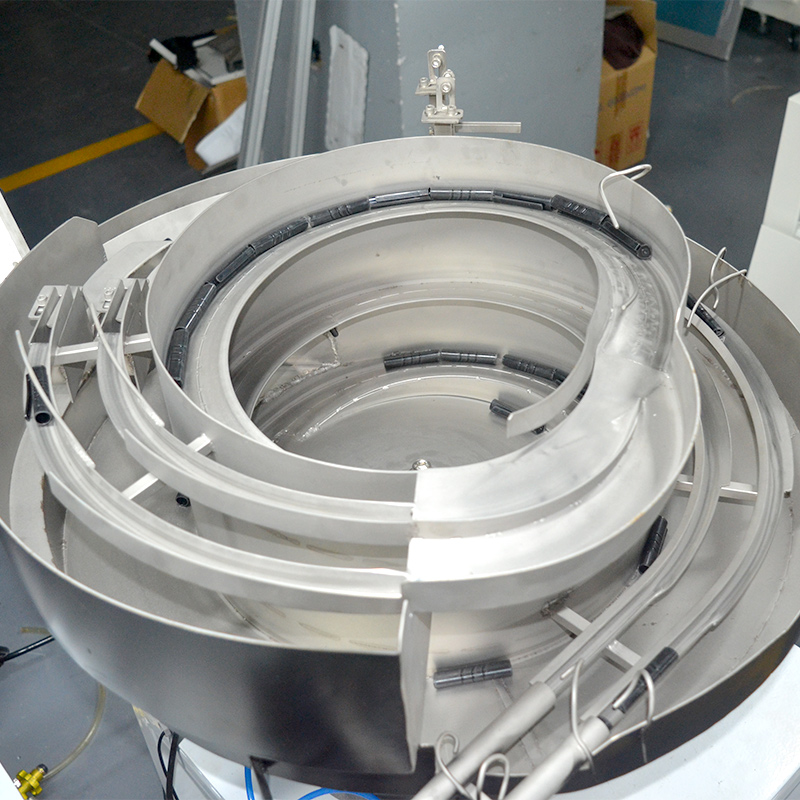

| printing color | 1、2、3、or4 | printing station | 14 |

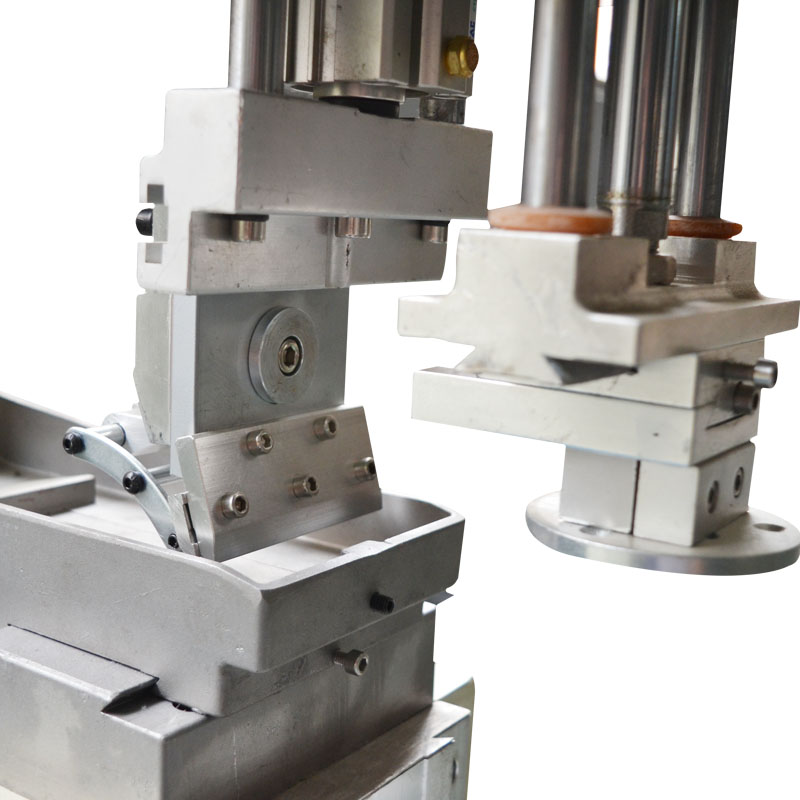

| oil cup | Ø90mm | Rubber head stroke | 80mm |

| Cylinder stroke | 225mm | maximum printing speed | 800pcs/hr |

| maximum printing speed | 220V 50Hz | Air pressure requirements | 6bar |

| Dimensions | 980*840*1350mm | machine weight | 137kg |

Main performance

①Microcomputer control, practical functions and easy operation.

②Using high-quality steel structure, light and solid;

③ Independent glue head speed adjustment;

④The oil roller is rolled and filled with ink, which is convenient for assembly, disassembly and cleaning;

⑤ Automatic balance oil knife, scraping oil cleanly;

⑥ Built-in four-digit automatic counter;

⑦The glue head can be empty before and after the glue head to prevent the ink from drying up when suspended;

⑧ Built-in multi-level speed control to meet different printing requirements.

Machine maintenance

① Before going to work, clean up the sundries on the machine and wipe the machine clean. Lubricating grease should be added regularly to moving parts such as guide rails, guide posts, and bearings.

② The workpiece table is a key component that affects the printing quality. It prevents the impact of hard objects. During printing, the ink cannot be removed. Organic solvents such as Tianna water drip onto the work surface.

③ The electric control panel and buttons should be prevented from being damaged by direct or indirect contact with solvents such as Tianna water, boiled oil and water.

④ The frame paint is to keep the machine from rusting, to prevent damage caused by direct or indirect contact with solvents such as Tianna water, boiled oil and water.

⑤ Drain the sewage and dirt in the oil mist combiner in time. To prevent the pneumatic components from being fed into the normal operation, clean the cup body regularly, and add Peng 2 lubricating oil to the oil cup of the oil mist combiner.

⑥ When adjusting the restrictor valve, the tightening nut must be loosened before adjusting by hand. The handle screw on the machine is used for positioning. After firmly positioning, there is no need to tighten it with excessive force.

⑦ After get off work, turn off the power/air source, clean the wire mesh, and keep it properly. Dust/pressure/hard object piercing.

TaoXing Company Introduction

Taoxing automatic screen printing machine video compilation

Service / FAQ

Guarantee

① We provide comprehensive one-stop services, customer training and satisfied after sales services.

② Online support, video technical support for troubleshooting manufacturing problems, engineers are available to service oversea as necessary.

③ Sold enjoy one year of free equipment warranty and lifetime technical support.

Guarantee for Delivery

Safety and fast logistic ensures the goods are delivered on the right time

1. Packing: Plywood Case for Each Machine

2. Payment terms: T/T (50% deposit to start the production, 50% paid before delivery)

3. Delivery date:60 business days after received the payment.

4. Departure of port: By sea from Shanghai or Ningbo

5. Delivery means: By sea by land

A: We are a professional manufacturing factory specialize in printing equipment with more than 20 years experience, committed to supplying our customer top quality and dedication to the constant improvements of quality, reliability, productivity and the competitiveness of our products and services.

A: Please send us an inquiry directly. We need to get specific details, such as material, size, color, thickness, quantity, etc.

A: Yes, we have a professional technique team, we could produce the machine depends on your requirements.

A: We accept TT/LC/PAYPAL/Western union, every payment term we can discuss.

A: All Taoxing products carry up to a full year warranty. Supply wearing parts with favorable price and long term after-sales service. We believe in total customer satisfaction, aside from our no-hassle guarantee.

Screen printing was a technique first used by the Chinese almost 2000 years ago. It is widely used at home and abroad. Chinese printing machine market has already become the focal point of the world have opened up. We have teams of experienced technical experts and professionals providing most professional and just-in-time technical consults and services, timely supply of spare parts in place.

If you are still confused how to start printing work, don’t worry, contact us and we will help you out!! No mater you are a green hand, we will train you up-to-date technology skills, and keep an eye on your business opportunities. Our friendly and professional team that is able to handle all your inquiries whenever you need.