Scope of Application

It is suitable for the rapid drying of solvent inks and the drying of general water-containing items. Such as: paper printing, chemical products, glass, plate, PVC, metal nameplates, etc.

Main parameters

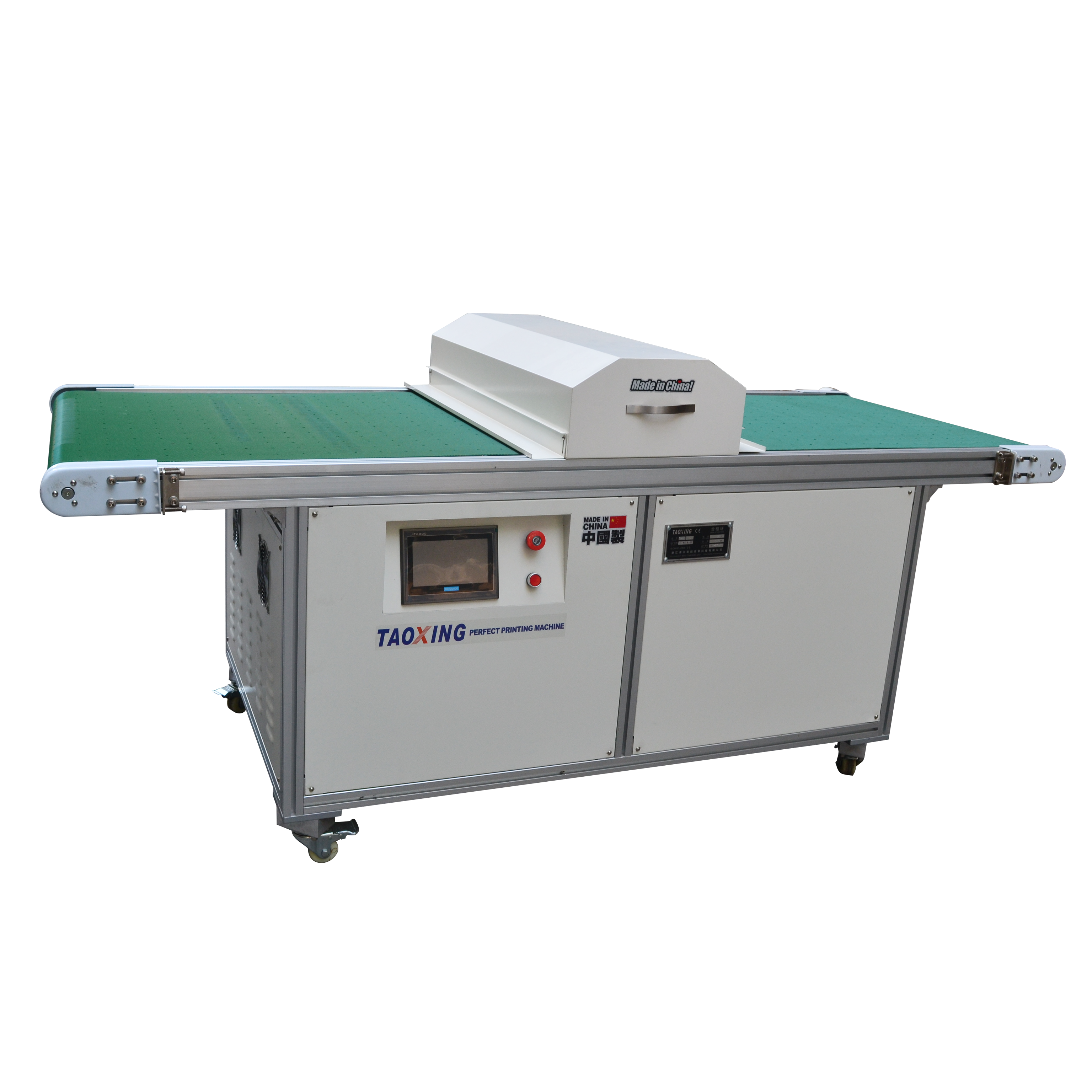

| Model | TX-800IR | Loading Section | 2000mm |

| Output section | 2000mm | IR heating Section | 2000mm *7Group |

| Cooling Section | 4000mm | Belt Width | 800mm |

| Power | 75KW | heating method | To be determined |

| Voltage | 380V | Total Length | 22000MM |

Production material

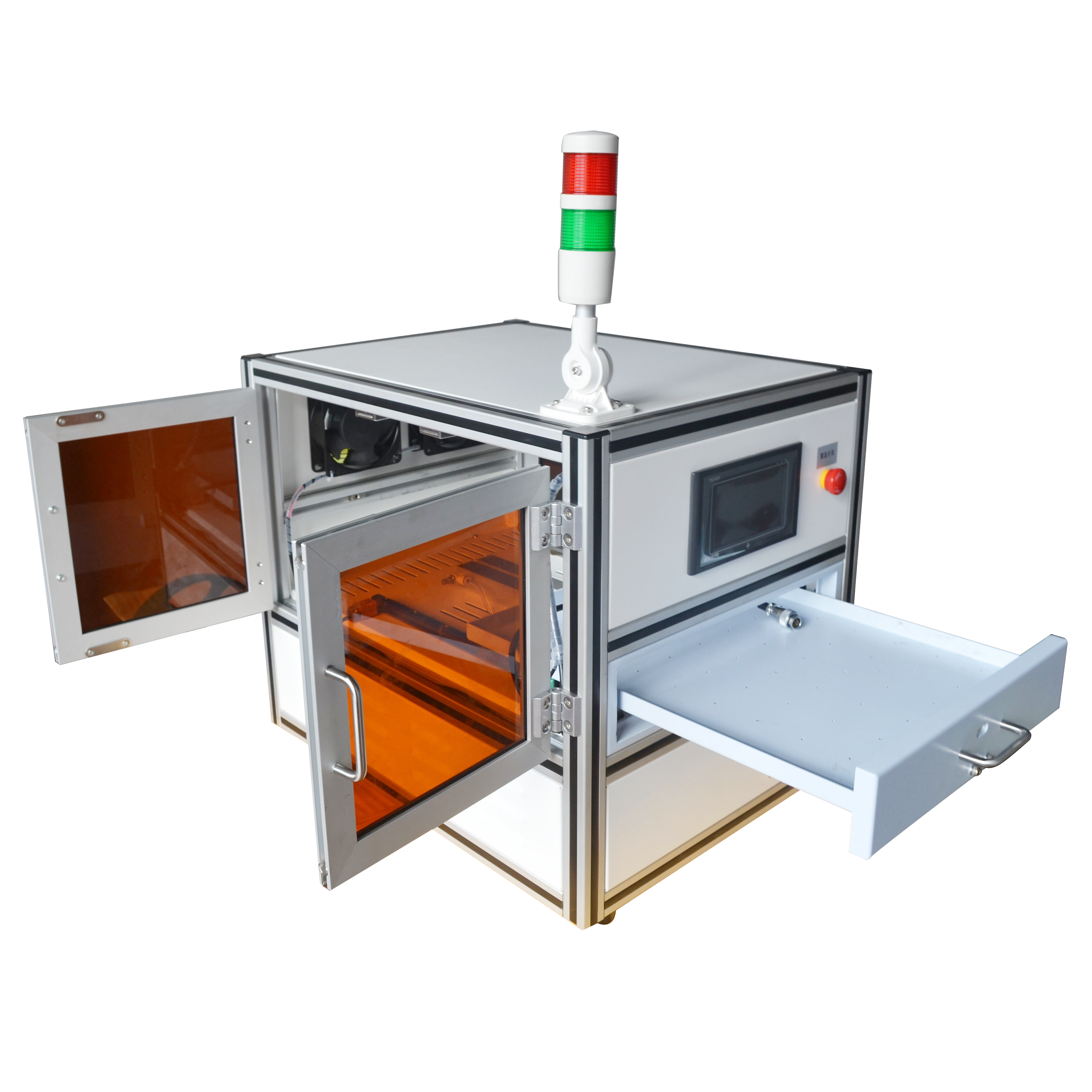

1.Heat curing oven:

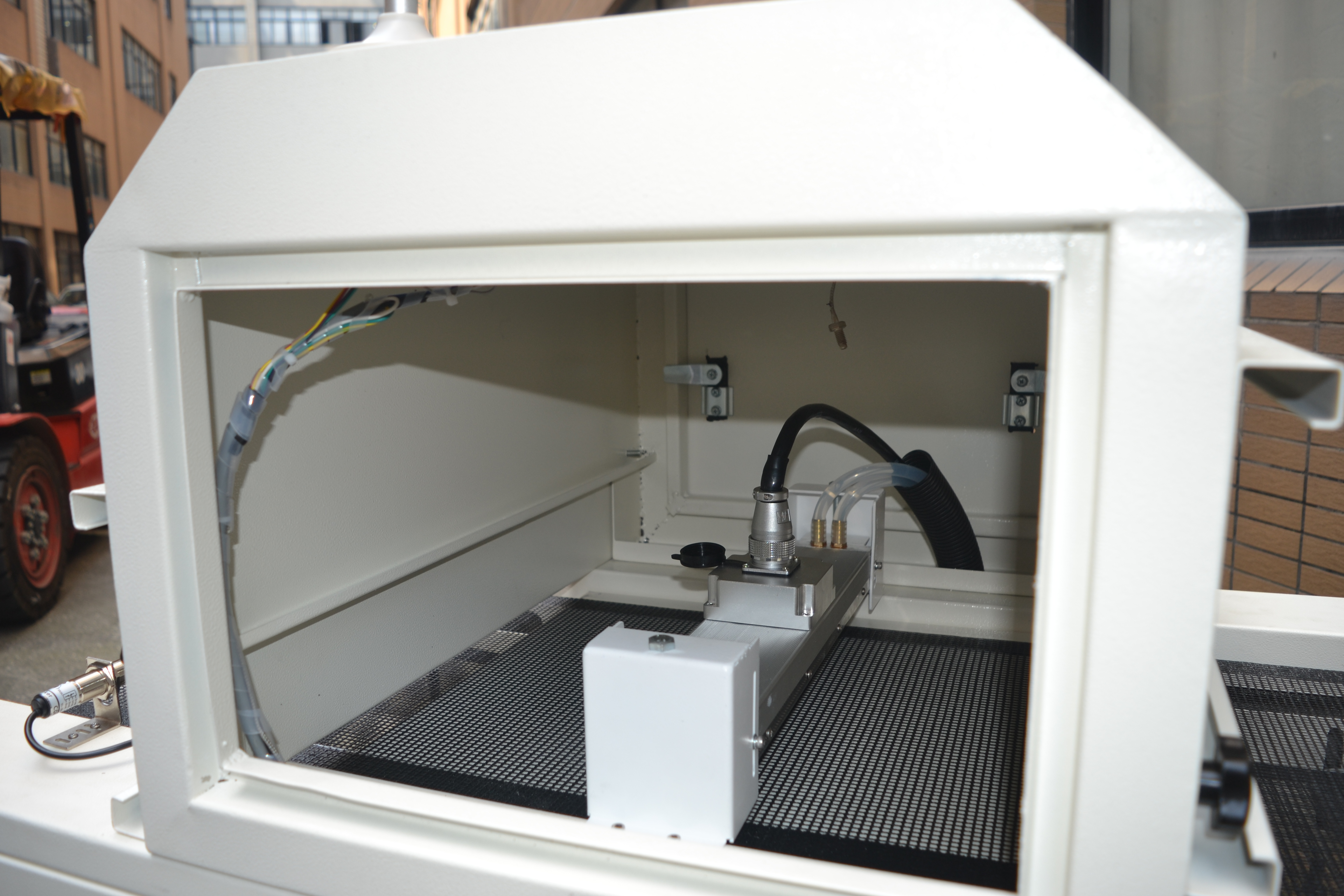

curing oven:100mm insulation board(insulation cotton,the inner plate is stainless steel plate,the outer plate is a 2mm cold rolled plate)

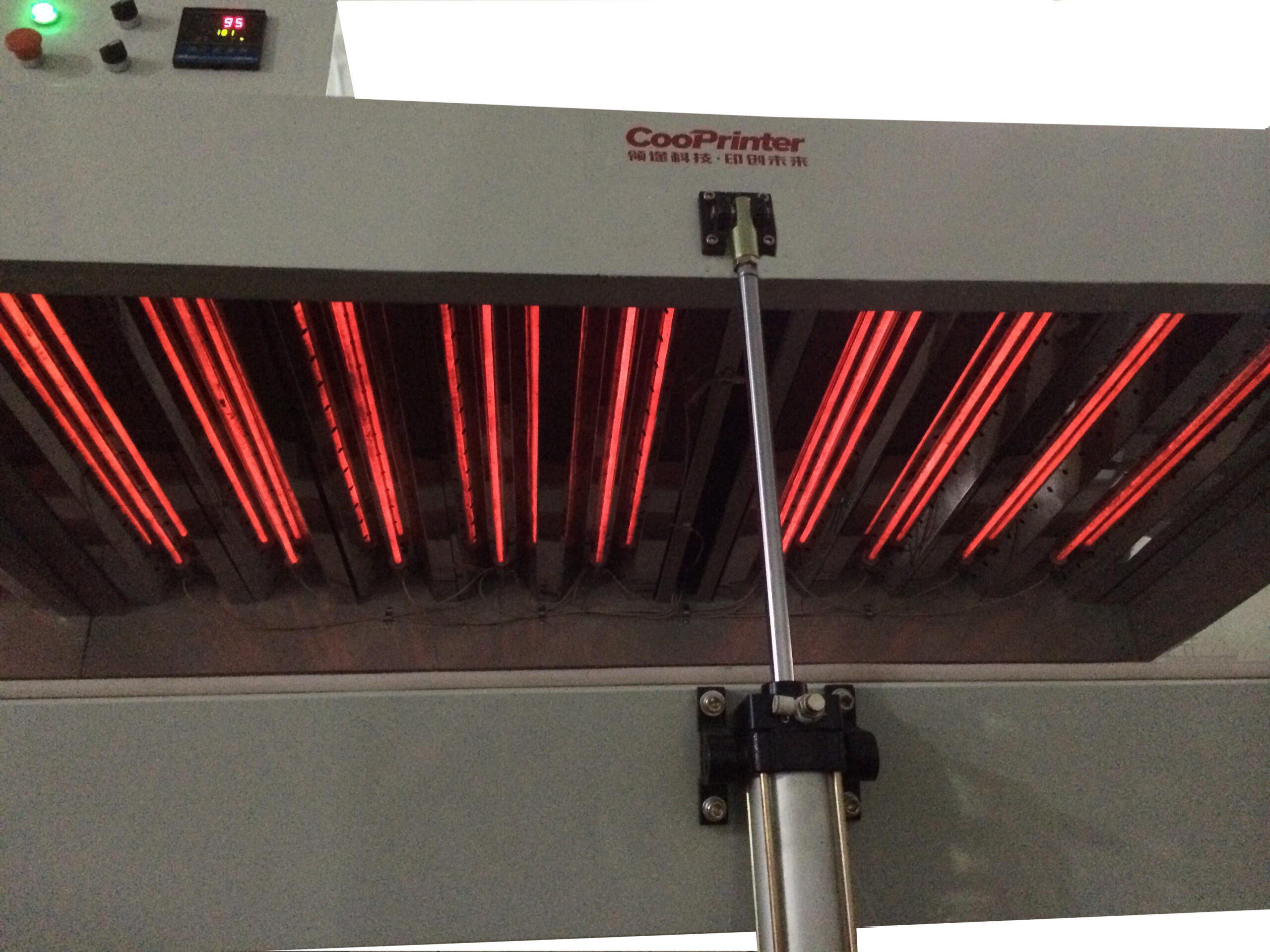

2.Heating source:380V 63 infrared heating tubes

Single heating length:1KW

Total heating power:63KW

The heating system is divided into one control, one temperature control and one temperature display in each group.

Heating temperature requirement:Room temperature – 200 degrees (adjustable)

☆Conveyor system:

Speed range:1-5m/min

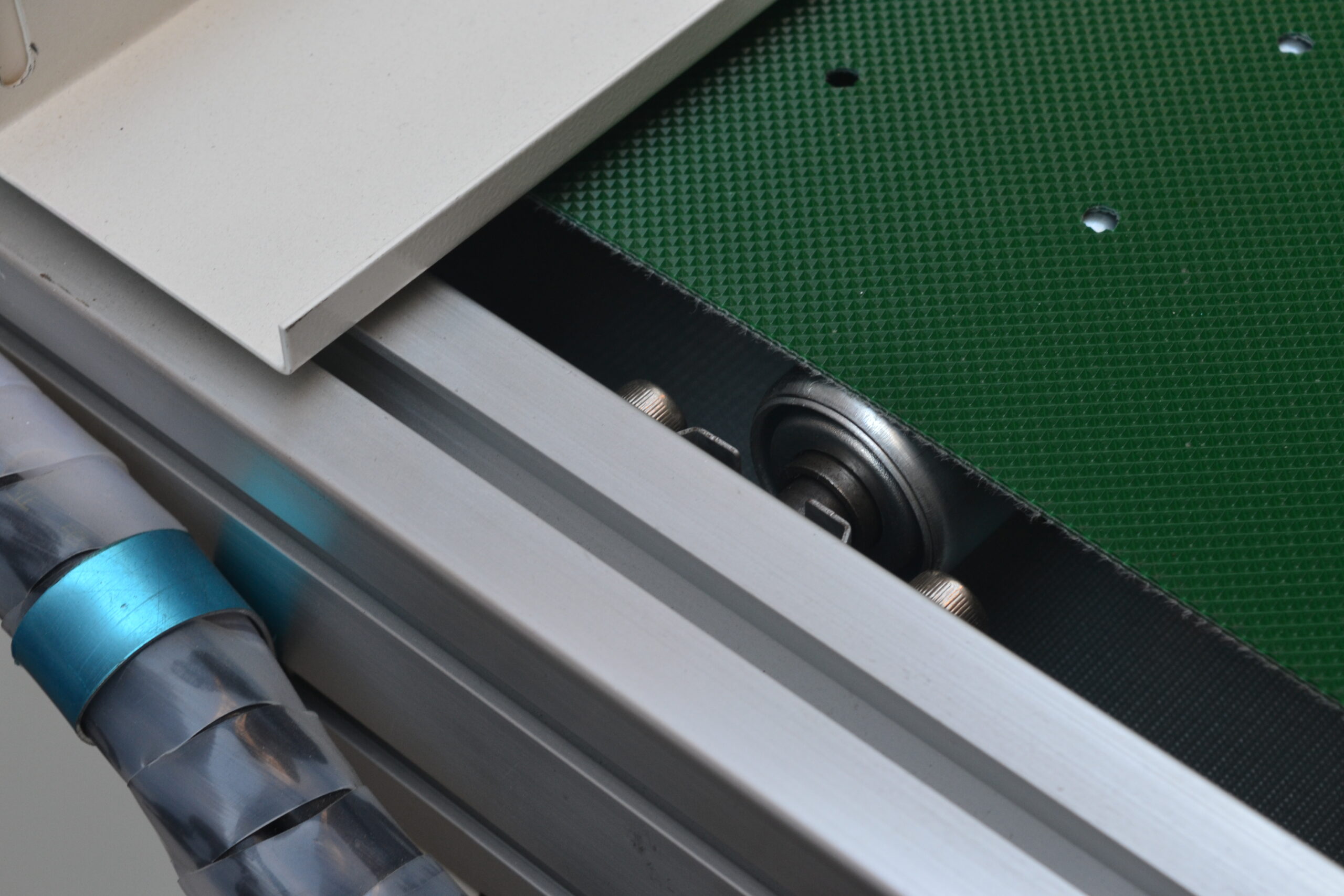

Conveyor belt:Adopting high temperature resistant Teflon mesh belt, the transmission speed is stable, no impact and no noise

Features

Our company adopts the latest foreign advanced technology and adopts high performance infrared ray tube heating method to accelerate the drying speed of ink.

- The heating zone of the machine is 14 meters in total and 7 heating sections.

- Infrared ray +PID uninterrupted power supply = energy

- The heating part of the machine adopts infrared lamp heating, with high energy of infrared ray and strong penetration rate, can makethe drying material to achieve the best drying effect.

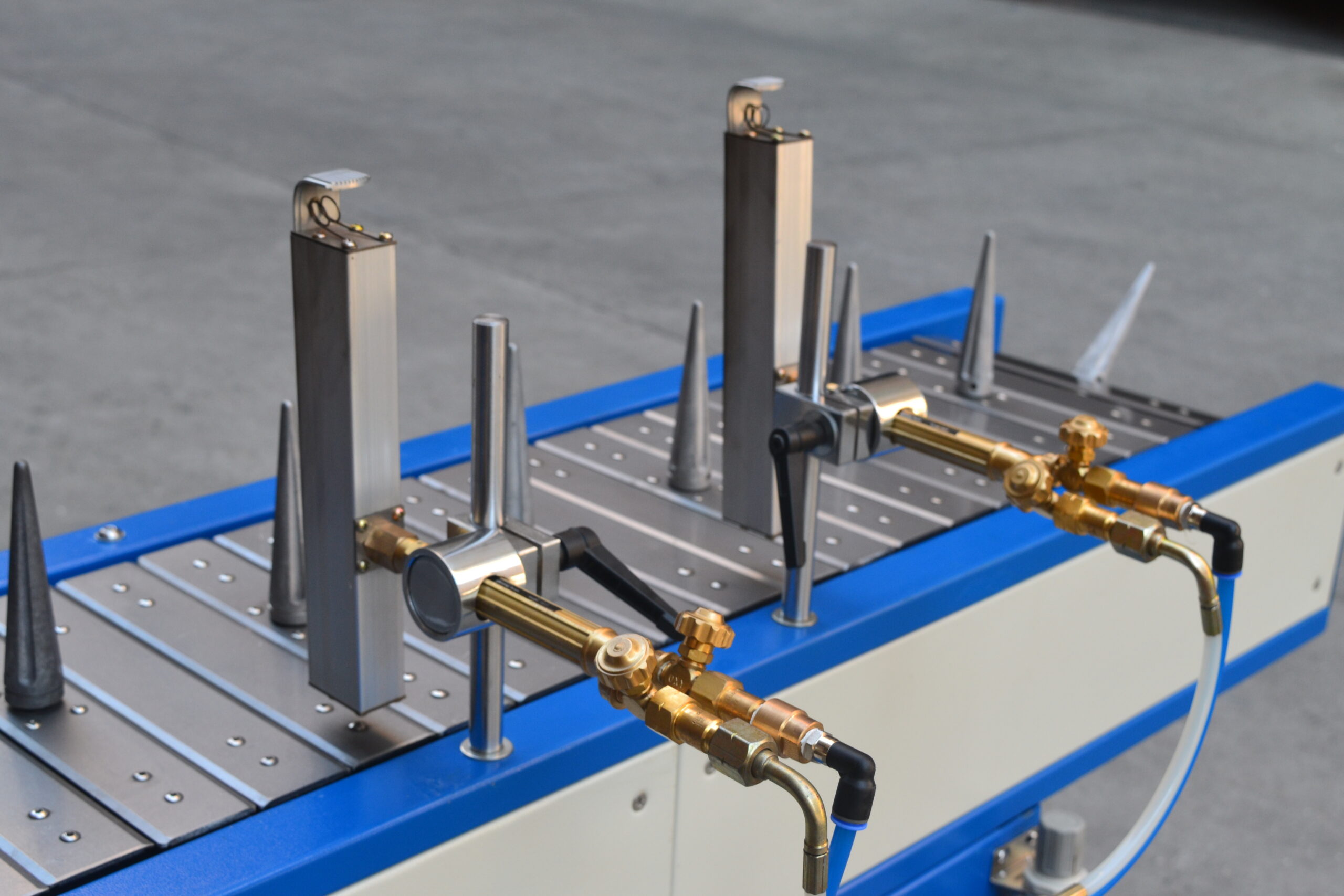

- The Lamp installation port is located at one side of the dryer for easy maintenance.

- The drying system adopts a pneumatic side cover design for easy cleaning and maintenance.

- Adoptfrequency conversion to regulate speed.

- The temperature control system is divided into 7 sections, each section separately controls the temperature, and each section has a temperature control meter. As long as one section of the temperature control is expressed to the set temperature, the heating lamp will stop heating, ensuring that the temperature in the box does not exceed the set temperature.

- When the drying room temperature is lower than the set temperature, the lamp tube is heated rapidly. When the drying room temperature is close to the set temperature, the lamptube is heated slowly. When the drying room temperature exceeds the set temperature, the lamp tube stops heating.

- The electric heating pipe terminal is protected by pressure porcelain, and the temperature resistant wire tube is resistant to high temperature.

- The exhaust fan adopts high temperature insulation grade motor.

- The whole machine adopts separate structure to facilitate inspection and maintenance.

- Conveyor belt displacement, using fixed or pneumatic control device to ensure that the mesh belt will not deviate,in order to achieve the purpose of the mesh belt does not run off!

- Conveyor speed controller with scale display and speed rate accuracy adjustment.

- The joint of oven and oven is fully sealed, and the lamp position in the oven is evenly distributed.

- Add the steel wire toboth sides of the drying tunnel.

- In the drying tunnel, the cable is made of high temperature resistant materials, and the joint must be wrapped with high temperature resistant material.

- Adopt variable frequency motor.

- The temperature probe can be adjusted in length in the drying tunnel. The rod probe’sdetection length is not less than 10

- Because the length of the drying tunnel is too long, an anti-drop hosting or bracket is added under the drying tunnel to prevent the mesh belt from falling, and they are placed for every 25cm of the length.

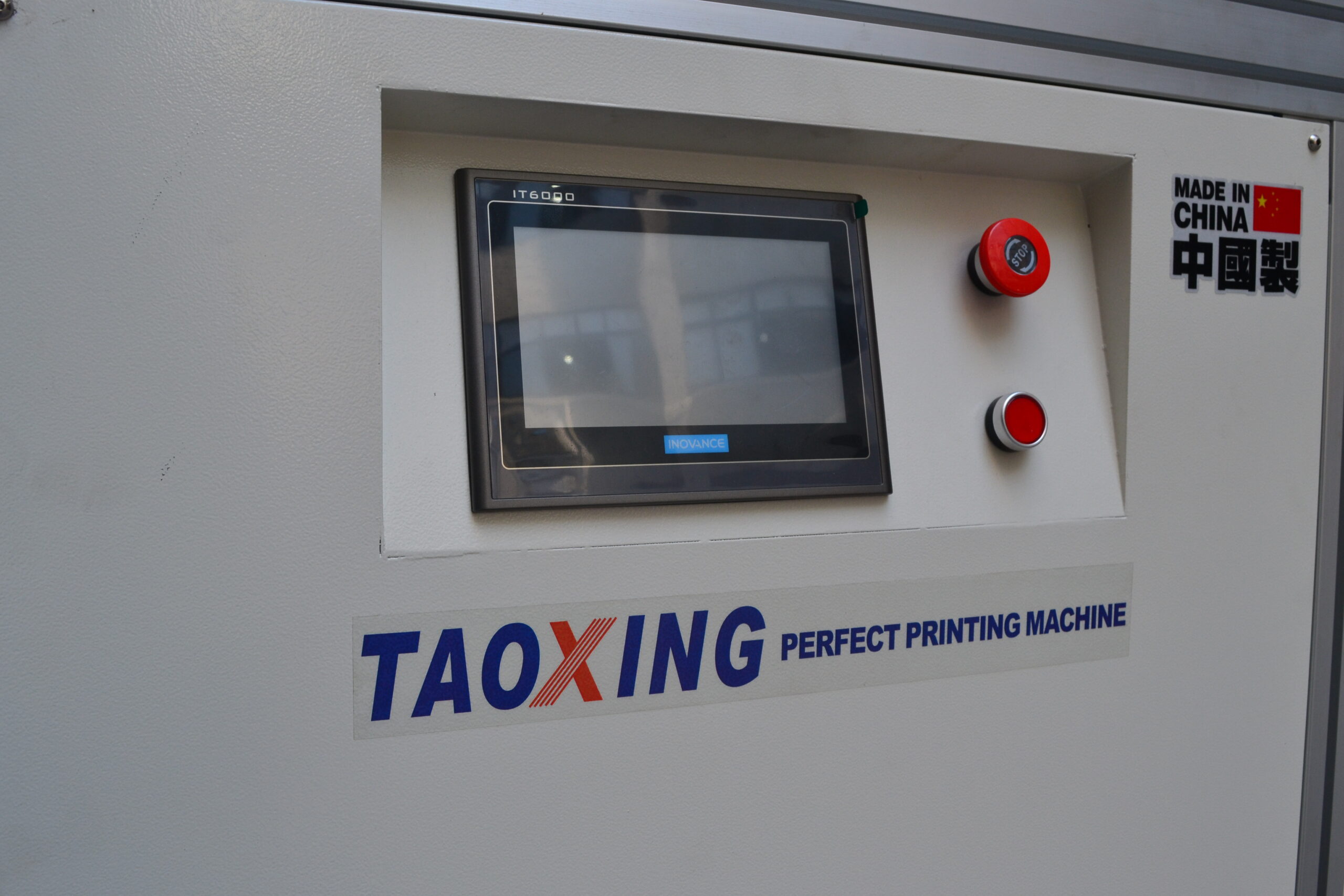

TaoXing Company Introduction

Taoxing automatic screen printing machine video compilation

Service / FAQ

Guarantee

① We provide comprehensive one-stop services, customer training and satisfied after sales services.

② Online support, video technical support for troubleshooting manufacturing problems, engineers are available to service oversea as necessary.

③ Sold enjoy one year of free equipment warranty and lifetime technical support.

Guarantee for Delivery

Safety and fast logistic ensures the goods are delivered on the right time

1. Packing: Plywood Case for Each Machine

2. Payment terms: T/T (50% deposit to start the production, 50% paid before delivery)

3. Delivery date:60 business days after received the payment.

4. Departure of port: By sea from Shanghai or Ningbo

5. Delivery means: By sea by land

A: We are a professional manufacturing factory specialize in printing equipment with more than 20 years experience, committed to supplying our customer top quality and dedication to the constant improvements of quality, reliability, productivity and the competitiveness of our products and services.

A: Please send us an inquiry directly. We need to get specific details, such as material, size, color, thickness, quantity, etc.

A: Yes, we have a professional technique team, we could produce the machine depends on your requirements.

A: We accept TT/LC/PAYPAL/Western union, every payment term we can discuss.

A: All Taoxing products carry up to a full year warranty. Supply wearing parts with favorable price and long term after-sales service. We believe in total customer satisfaction, aside from our no-hassle guarantee.

Screen printing was a technique first used by the Chinese almost 2000 years ago. It is widely used at home and abroad. Chinese printing machine market has already become the focal point of the world have opened up. We have teams of experienced technical experts and professionals providing most professional and just-in-time technical consults and services, timely supply of spare parts in place.

If you are still confused how to start printing work, don’t worry, contact us and we will help you out!! No mater you are a green hand, we will train you up-to-date technology skills, and keep an eye on your business opportunities. Our friendly and professional team that is able to handle all your inquiries whenever you need.