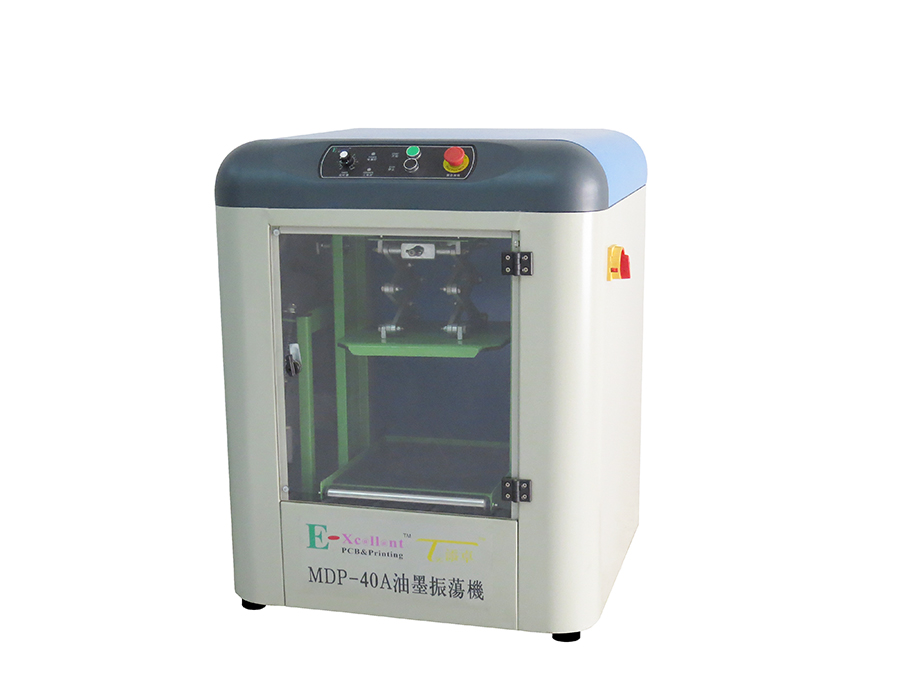

Single-suction Powder Coating Machine for Glitter Powder

Contact Us

Inquiry

Application:

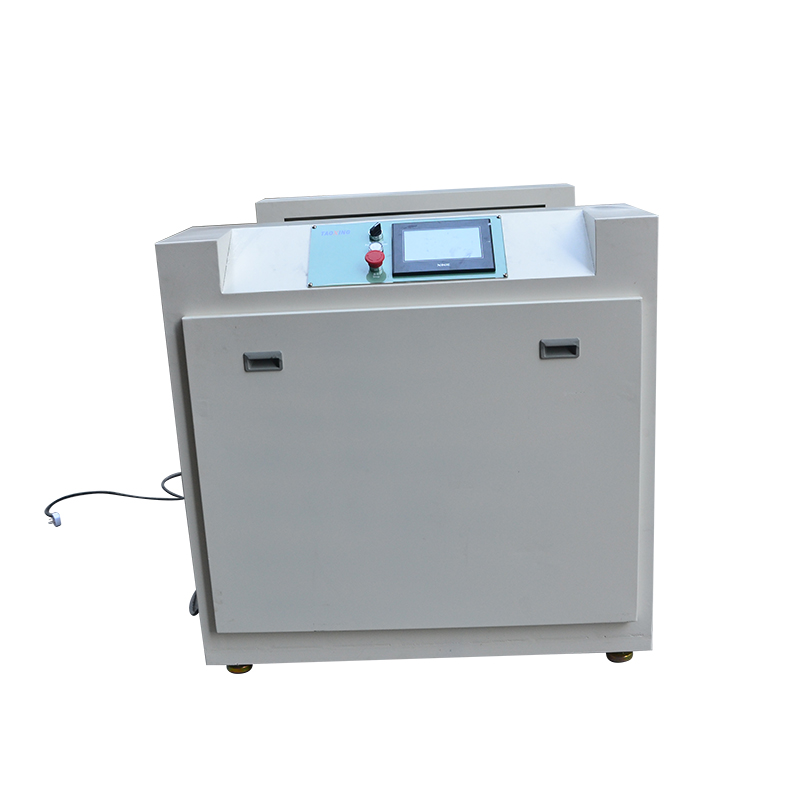

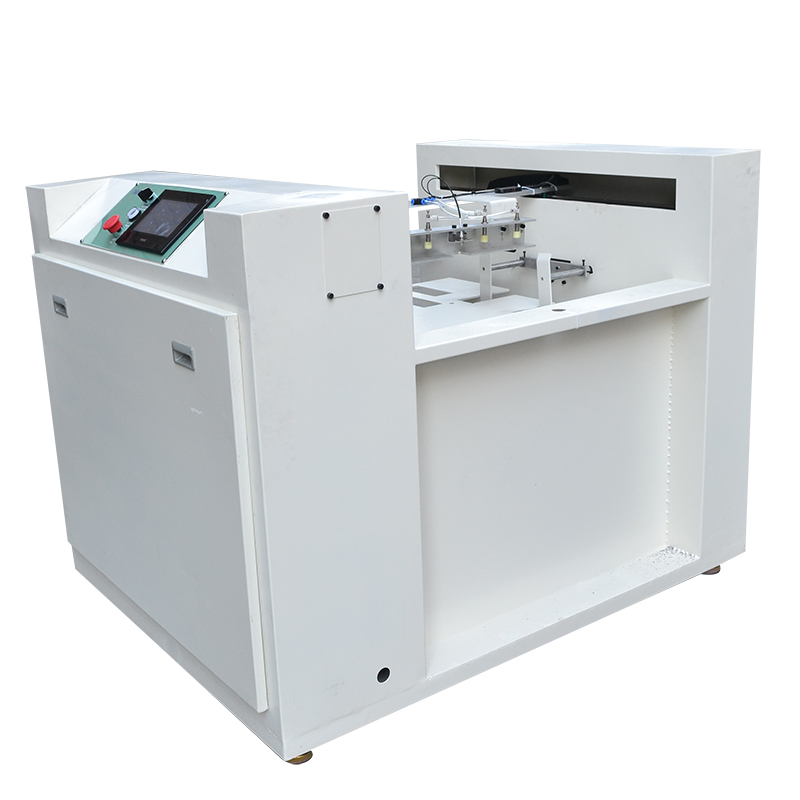

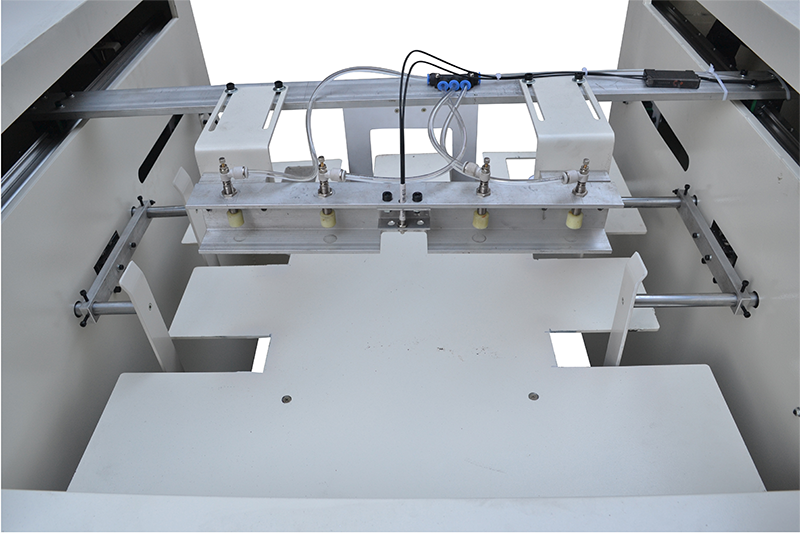

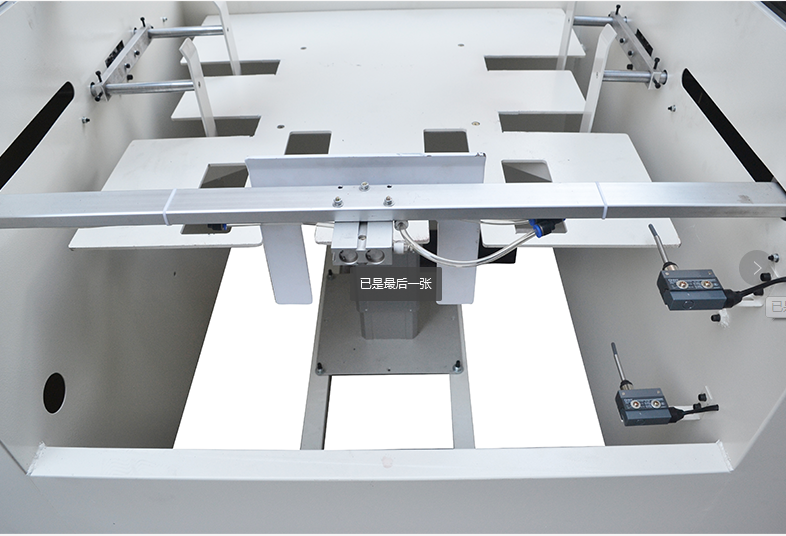

The automatic powder coating machine series is a kind of post-printing supporting machine that replaces the traditional hand-made glitter powder hot melt powder process. This machine is suitable for the powdering process of clothing trademarks, greeting cards, blessing characters, couplets, Christmas cards, tablets, etc. Easy to use, no dust pollution, automatic recovery, recycling of raw materials, etc., and the use of a screen printing machine can greatly improve the efficiency, increase the utilization rate of the hot melt powder of the glitter powder, and can make a variety of changes Glitter powder hot melt powder pattern. If the process requires, it can be conveniently connected to the drying, UV curing machine and other equipment at the back. This machine adopts upper and lower suction port design to prevent the occurrence of scratches on the surface of the film. It is the best post-press supporting equipment for the film glitter powder process.

Specifications:

| Model | TX-SF100D | TX-SF125D |

| Suction Type | Single Suction | Single Suction |

| Max Coating Width | 900mm | 1100mm |

| Max Material Thickness | 5mm | 5mm |

| Max Working speed | 1500m/h | 1500m/h |

| Voltage | 2.0KW 220V 50HZ | 2.0KW 220V 50HZ |

Main performance:

- The key parts of the machine, such as the conveyor belt and the frequency converter, all adopt imported parts, which are easy to use and flexible to adjust.

- The original powder spraying system enables the color powder to adhere to the printed matter evenly and smoothly.

- It is equipped with color powder recovery system, and the excess color powder is lightly pressed by the roller before drying to make it evenly balanced.

- Spreading powder-light roller pressing-recycling-drying, high efficiency and energy saving, completely solve the problem of uneven manual powder spreading, low efficiency, and color powder flying all over the sky.

- All transmission parts of the whole machine can be adjusted steplessly, which has the characteristics of high durability and good stability.

Configuration List:

| NO. | Configuration Name | Configuration Brand |

| 1 | Frequency Converter | Taiwan |

| 2 | switch | Shanghai Ergong |

| 3 | Fan | Taiwan |

| 4 | Motor | Taiwan |

| 5 | Geared Motor | Shanghai |

Machine Maintenance:

- Clean up the debris on the machine before going to work and wipe the machine clean. Lubricating grease should be added regularly to moving parts such as guide rails, guide posts, and bearings.

- The electronic control panel and buttons should be prevented from direct or indirect contact with solvents such as thinner, boiling oil and water, which may cause damage.

- The rack paint is to keep the machine from rusting, and it is necessary to prevent direct or indirect contact with solvents such as thinner, boiling oil and water from causing damage.

- When adjusting the restrictor valve, the tightening nut must be loosened before manual adjustment. The handle screw on the machine is used for positioning. After the positioning is firm, there is no need to tighten it excessively.

- After work, turn off the power/air supply.

TaoXing Company Introduction

Taoxing automatic screen printing machine video compilation

Service / FAQ

Guarantee

① We provide comprehensive one-stop services, customer training and satisfied after sales services.

② Online support, video technical support for troubleshooting manufacturing problems, engineers are available to service oversea as necessary.

③ Sold enjoy one year of free equipment warranty and lifetime technical support.

Guarantee for Delivery

Safety and fast logistic ensures the goods are delivered on the right time

1. Packing: Plywood Case for Each Machine

2. Payment terms: T/T (50% deposit to start the production, 50% paid before delivery)

3. Delivery date:60 business days after received the payment.

4. Departure of port: By sea from Shanghai or Ningbo

5. Delivery means: By sea by land

A: We are a professional manufacturing factory specialize in printing equipment with more than 20 years experience, committed to supplying our customer top quality and dedication to the constant improvements of quality, reliability, productivity and the competitiveness of our products and services.

A: Please send us an inquiry directly. We need to get specific details, such as material, size, color, thickness, quantity, etc.

A: Yes, we have a professional technique team, we could produce the machine depends on your requirements.

A: We accept TT/LC/PAYPAL/Western union, every payment term we can discuss.

A: All Taoxing products carry up to a full year warranty. Supply wearing parts with favorable price and long term after-sales service. We believe in total customer satisfaction, aside from our no-hassle guarantee.

Screen printing was a technique first used by the Chinese almost 2000 years ago. It is widely used at home and abroad. Chinese printing machine market has already become the focal point of the world have opened up. We have teams of experienced technical experts and professionals providing most professional and just-in-time technical consults and services, timely supply of spare parts in place.

If you are still confused how to start printing work, don’t worry, contact us and we will help you out!! No mater you are a green hand, we will train you up-to-date technology skills, and keep an eye on your business opportunities. Our friendly and professional team that is able to handle all your inquiries whenever you need.

.jpg)

.jpg)

-1.jpg)