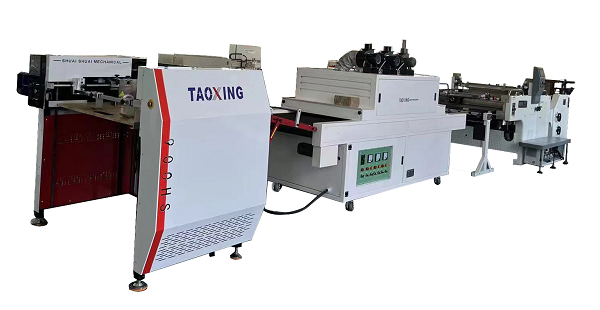

TX-GSP780 Automatic roller UV screen printing machine

Contact Us

Inquiry

Description and Application

TX-GSP780 full-automatic roller reciprocating screen printing machine is a mature product of Taoxing printing machine, which integrates high-speed, high-precision full-automatic single-color single-color screen printing machine.

Its printing range is wide, and it can print single-color printing and multi-color printing on paper (gold and silver cardboard, transfer paper, white paper), plastic film (PVC, PET, PP), self-adhesive and other single-sheet materials with a thickness of 90g~350g Overprinting, and local UV coating of printed matter can also be done at the same time.

The automatic cylinder screen printing machine meets the screen printing of a variety of inks and papers, and is especially ideal for overprinting of gold and silver in UV imitation metal inks. The main uses are in addition to ceramics, glass, enamel, bicycles, automobiles, furniture, The decal printing of trademarks such as lacquerware and sporting goods can also be used for the packaging and decoration of soft paper boxes, cartons, posters, tobacco and alcohol, and the printing of PVC and credit cards.

Parameter

| Model | TX-GSP780 |

| Max paper size | 780*540mm |

| Min paper size | 350*270mm |

| Max printing size | 780*520mm |

| Paper thickness | 90-350g/m2 |

| Frame size | 940*940 |

| Printing speed | 1000-3500sheet /hour |

| Total powder | 8.0KW |

| Weight | 3500kg |

| Size | 3100*2020*1270mm |

Main configuration and function

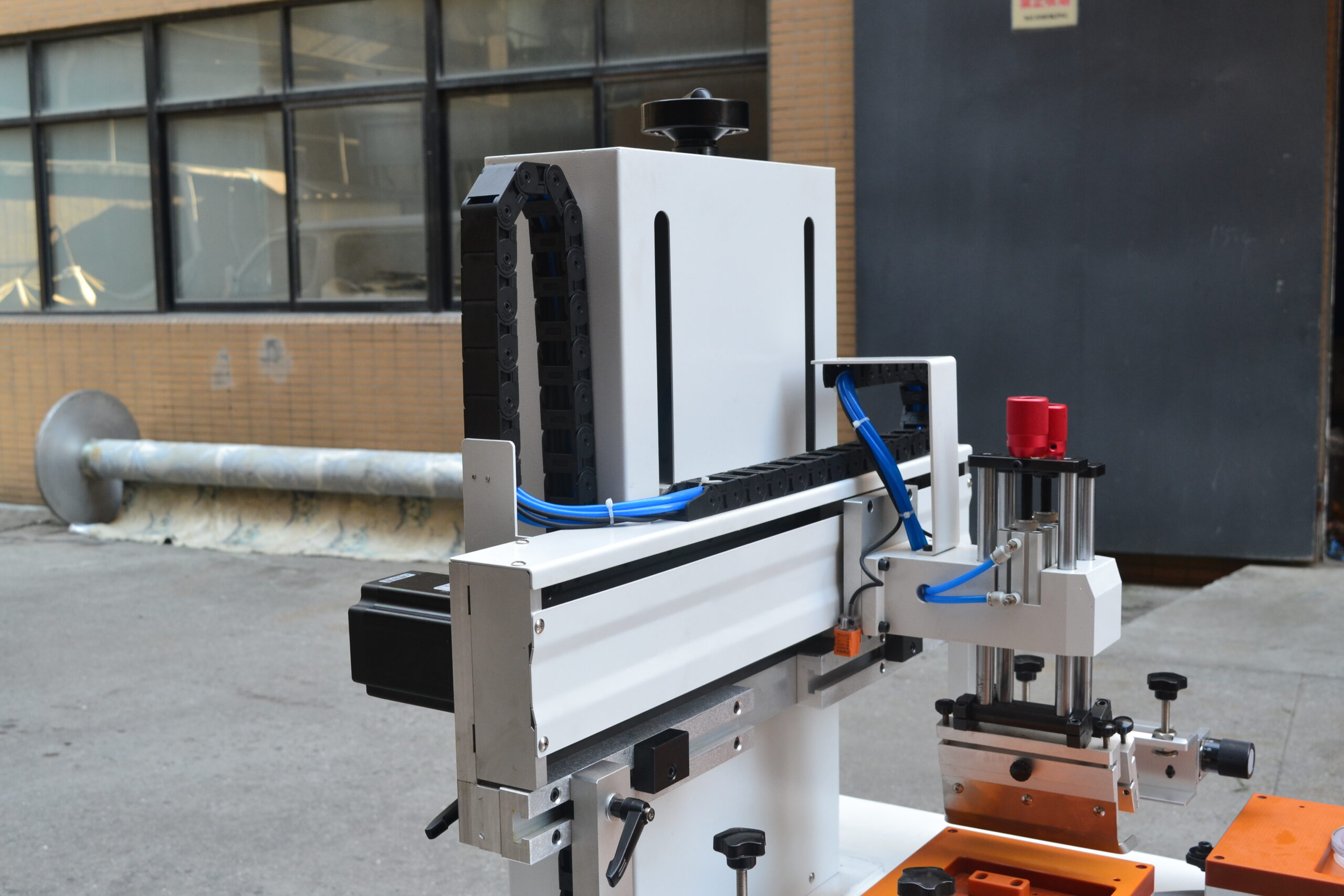

- Driven by a frequency conversion brake motor, the whole machine is controlled and operated by a Japanese Mitsubishi PLC

- programmable controller. The 7-inch Weilun touch screen operation interface displays all functional data, and the printing operation is simpler and more convenient;

- The whole process of printing inspection, there is a line failure, automatic shutdown of the pressure, reducing the waste of printing paper

- Set up a complete alarm system to remind the operator to carry out targeted troubleshooting, making maintenance easy and quick;

- The entire set of electrical components are imported from Schneider, Mitsubishi, and Omron, which greatly improves the stability of the electrical system and reduces the frequency and difficulty of maintenance and repair; Electrical control box The whole machine adopts Mitsubishi, Schneider Electric

6.The cast iron frame and some parts are precisely processed by the CNC “machining center” to ensure the accuracy of the main parts and ensure the stability and long-term rapid operation of the machine;

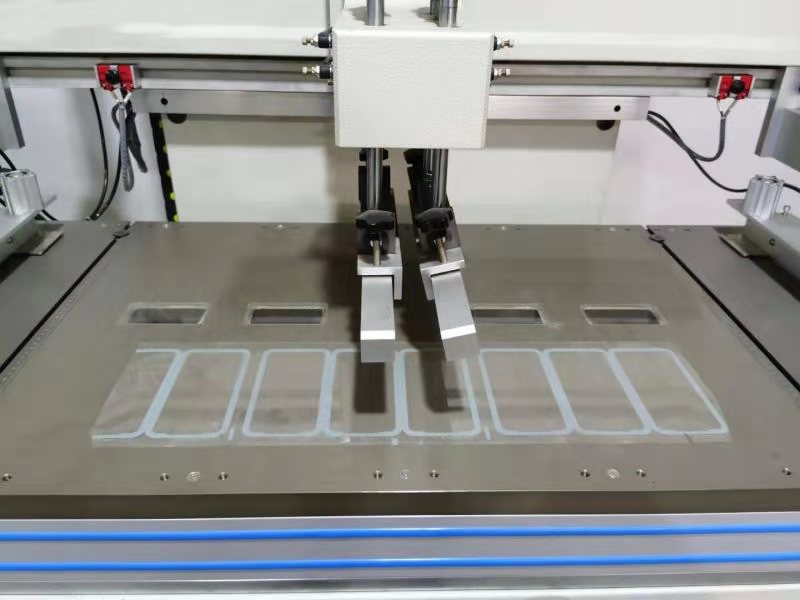

7.The printing cylinder is made of stainless steel 304 material (1.96mm), which is precise and durable; the elastic range of the gripper is designed to be flexible, which is convenient for adjustment at any time when printing on different thicknesses of paper;

8.Pneumatically controlled paper output table that can be turned 90 degrees, which facilitates the cleaning and loading and unloading of the screen; with the screen fine-tuning device, the screen can be adjusted in all directions from top to bottom, front to back, and left to right;

9.The appearance is covered by a metal cover formed by laser cutting of cold press plates and CNC bending. Acrylic flat varnish and two-component acrylic varnish are used to effectively prevent the corrosion of the equipment by printing solvents and maintain a clean appearance.

10.The whole series of equipment adopts Taiwan Airtech pneumatic components; the screen frame is clamped with mechanical clamps;

11.More than 98% of the bearings of the whole machine adopt NTN, NSK, IKO imported bearings;

Technical parameters of production assembly workshop:

| Model

parameter |

TX-GSP780 |

| Max paper size (mm) | 800×560 |

| Min paper size (mm) | 450×350 |

| Max printing size (mm) | 780×530 |

| Paper thickness(g/m2) | 90-300 |

| Frame size (mm) | 940×940 |

| Printing speed (sheet/H) | 800—3000 |

| power(kw) | 8.0 |

| Weight(kg) | 4500 |

| Size(mm) | 3600×2350×1320 |

TaoXing Company Introduction

Taoxing automatic screen printing machine video compilation

Service / FAQ

Guarantee

① We provide comprehensive one-stop services, customer training and satisfied after sales services.

② Online support, video technical support for troubleshooting manufacturing problems, engineers are available to service oversea as necessary.

③ Sold enjoy one year of free equipment warranty and lifetime technical support.

Guarantee for Delivery

Safety and fast logistic ensures the goods are delivered on the right time

1. Packing: Plywood Case for Each Machine

2. Payment terms: T/T (50% deposit to start the production, 50% paid before delivery)

3. Delivery date:60 business days after received the payment.

4. Departure of port: By sea from Shanghai or Ningbo

5. Delivery means: By sea by land

A: We are a professional manufacturing factory specialize in printing equipment with more than 20 years experience, committed to supplying our customer top quality and dedication to the constant improvements of quality, reliability, productivity and the competitiveness of our products and services.

A: Please send us an inquiry directly. We need to get specific details, such as material, size, color, thickness, quantity, etc.

A: Yes, we have a professional technique team, we could produce the machine depends on your requirements.

A: We accept TT/LC/PAYPAL/Western union, every payment term we can discuss.

A: All Taoxing products carry up to a full year warranty. Supply wearing parts with favorable price and long term after-sales service. We believe in total customer satisfaction, aside from our no-hassle guarantee.

Screen printing was a technique first used by the Chinese almost 2000 years ago. It is widely used at home and abroad. Chinese printing machine market has already become the focal point of the world have opened up. We have teams of experienced technical experts and professionals providing most professional and just-in-time technical consults and services, timely supply of spare parts in place.

If you are still confused how to start printing work, don’t worry, contact us and we will help you out!! No mater you are a green hand, we will train you up-to-date technology skills, and keep an eye on your business opportunities. Our friendly and professional team that is able to handle all your inquiries whenever you need.