Different Materials, Different Needs

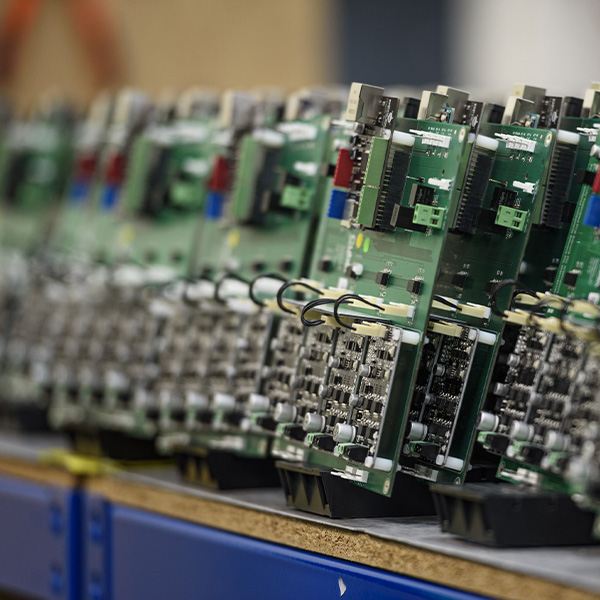

Glass, metal, PCB, plastics, or magnetic surfaces all require specific ink, pressure, and curing combinations.

Glass, metal, PCB, plastics, or magnetic surfaces all require specific ink, pressure, and curing combinations.

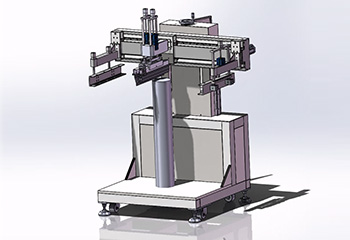

From flat to curved or cylindrical surfaces — each geometry demands a unique printing setup.

Standard models rarely fit perfectly; custom adjustments in jigs, dimensions, automation, and curing ensure higher yield and accuracy.

Improved yield and accuracy (±0.1mm alignment)

Increased production capacity (automatic loading and unloading, in-line curing)

Reduces manual labor and ensures consistency

Adapts to customers' existingproduction lines and factory space

Step 1 | Customer Needs Matching | 1. Requirements Analysis: Printing Material/Format/Precision/Automation Level; 2. Customize a solution (including technical specifications) and machine price quote based on the customer's needs and samples provided; 3. Customer Confirms Solution and Signs Contract. |  |

Step 2 | Machine Design | 1. Optimize the mechanical structure based on customer needs, such as raising or lowering the workbench. 2. Customize the electrical system: For example, adapt explosion-proof motors, switches, and control cabinets to meet explosion-proof requirements. 3. Develop customized CAD drawings and electrical schematics for customer approval. |  |

Step 3 | Sheet Metal Chassis Production | Customized welding and sheet metal spraying of chassis frame; |  |

Step 4 | Parts Production | 1. Special component procurement: such as large-size screen frames, high-precision servo motors, and precision positioners; 2. Non-standard component processing: Custom scrapers, specialized jigs/fixtures, etc. 3. Component quality inspection: Focusing on testing customized dimensional tolerances and fixture performance parameters. |  |

Step 5 | Machine Assembly and Commissioning | 1. Customized Mechanical Assembly: such as adding an automatic loading and unloading mechanism; 2. Electrical System Wiring: Connecting according to customized principles, adapting to special sensors and controllers, etc. 3. Initial Power-On Test: Ensures that customized components are receiving proper power. |  |

Step 6 | Printing Proofing | 1. Test the printing results using customer-provided samples, patterns, and inks. 2. Customer confirms that the printing results and efficiency meet the custom requirements. |  |

Step 7 | Delivery and After-Sales | 1. Customized packaging and logistics delivery; 2. Remote guidance on installation and commissioning, including explanations on special functions and machine maintenance; 3. After-sales support: Spare parts and technical consultation. |  |

From small PCBs to large glass panels

Flat, curved, cylindrical, and special-shaped parts

Manual/Semi-automatic/Fully automatic + PLC/Servo

Can be integrated with conveyor lines, robotic arms, and AGVs

UV, IR, hot air, multi-mode connection possible

Conductive ink printing, scratch-resistant coating, marking and coding

Customized Cylindrical Printing Press + UV Curing → Increased Production Capacity 2.5-fold

Explore More

Customized Cylindrical Printing Press + UV Curing → Increased Production Capacity 2.5-fold

Explore More

Customized Cylindrical Printing Press + UV Curing → Increased Production Capacity 2.5-fold

Explore More

Customized Cylindrical Printing Press + UV Curing → Increased Production Capacity 2.5-fold

Explore MoreOver 10 years of industrial screen printing experience, with customers in over 110 countries

One-stop service: Printing + Curing + Platemaking + Consumables

Professional engineering team: Quick response to custom needs

Complete after-sales service: Installation, training, remote maintenance, and long-term spare parts supply