Home / All / Post-printing drying equipment / IR Drying Machine / Small Infrared Drying Tunnel TX-IR80-250 Belt Drying Equipment For Screen Printing

Small Infrared Drying Tunnel TX-IR80-250 Belt Drying Equipment For Screen Printing

IR drying tunnel machine widely apply for screen printing. electronic products, plastic tube, gloss bottle.

Detail Information

Scope of Application of Small IR Drying Tunnel Machine

This small infrared drying tunnel machineis suitable for the rapid drying of solvent-based inks and the drying of general items containing moisture, such as: printed paper, chemical products, glass, sheets, PVC, fabrics, and metal nameplates.

The general features comprise air handling, use of forced airflow accelerating drying/curing processes, use of high-volume circulation blower that reduces energy costs, separate dedicated blowers for achieving circulation & exhaust control center.

Further, the system also comes with digital keypad with digital display, air-cooled electrical control cabinet for ensuring long life of electrical components as well as conveyor belt made of imported anti static heat-resistant, coated fiberglass coating so as to provide maximum process efficiency standards.

Main parameters of Small IR Drying Tunnel Machine

Model :TX-IR80-250

Width of belt: 800mm

Length of feeding section: 250mm

Length of feeding: 250mm

IR heating section: 2000mm

Feed inlet height: 120mm

Heating method: Infrared lamp tube ( glass )

WorkingPower: AC380V / 50HZ / 12KW

Machine size: L2500*W1200*H1400mm

Gross weight: 260kg

Overhaul: Pneumatic side lifting

Features and Performance

1. Materials used in production

①Thermosetting oven:

Curing box: 80mm insulation board ( filled with aluminum silicate cotton , inner board is galvanized sheet , outer board is 2mm cold rolled sheet)

Inner liner width : 850mm; Outer width: 1050mm

2. Heating source: 380V , 12 infrared heating tubes

Single heating element length: 800 mm , 1KW

Total heating power: 12 KW

The heating system is divided into temperature control and temperature display.

Heating temperature requirement: room temperature - 180 degrees Celsius (adjustable)

Relative temperature difference: ± 3-5 degrees Celsius (to ensure uniform heating temperature)

Temperature control accuracy: ± 2 degrees Celsius

Circulating fan: 1 unit, power 0.45KW

3. Transmission system: Speed range: 0-10 m/min

Conveyor belt : Made of high-temperature resistant Teflon mesh belt, ensuring stable conveying speed, no impact, and no noise.

Features of this machine:

Our company adopts the latest advanced foreign technology, using high-performance infrared lamps and circulating hot air heating to accelerate...

This improved the ink drying speed .

1.The heating zone of this machine is 2 meters long and consists of 1 heating section.

2.Infrared radiation + PID uninterruptible power supply + powerful circulating air = high efficiency and energy saving.

3.The heating element of this machine uses infrared lamps , which have high energy and strong penetration, achieving the best drying effect for the dried items.

4.The lamps are located in sections at the top of the inner cavity, with the lamp mounting ports on one side of the dryer for easy maintenance.

5.The drying system features a manually operated side-opening cover design for easy cleaning and maintenance.

6.Utilizing frequency conversion Speed adjustment .

7.Contactors and air switches are domestically produced.

8.When the drying chamber temperature is lower than the set temperature, the lamps heat up quickly; when the drying chamber temperature approaches the set temperature, the lamps heat up slowly.

9.The heating element terminals are protected by pressure-resistant ceramic, and the heat-resistant conduit is made of high-temperature resistant material.

10.The circulating fan and exhaust fan use high-temperature resistant motors with high insulation ratings.

11.The machine adopts a split structure, which facilitates inspection and maintenance.

12.The conveyor belt displacement is adjusted using fixed or pneumatic adjustment devices to ensure that the conveyor belt does not deviate from its designated path.

13.Conveyor belt speed controller with scale display and adjustable speed accuracy.

14.The joints between the ovens are fully sealed, and the lamps inside the drying tunnel are evenly distributed.

15.Inside the drying tunnel, cables must be made of high-temperature resistant materials, and joints must be wrapped with high-temperature resistant materials.

16.A variable frequency motor is used.

17.Inside the drying tunnel, an adjustable-length rod-shaped temperature probe is used. The probe length is no less than 10 cm.

18.Because the drying tunnel is too long, a support or bracket is added under the conveyor belt to prevent it from sagging.

19.The Teflon mesh belt is available in black or brown.

20.The chassis is white or gray.

Product Details

Application

Glass Panel

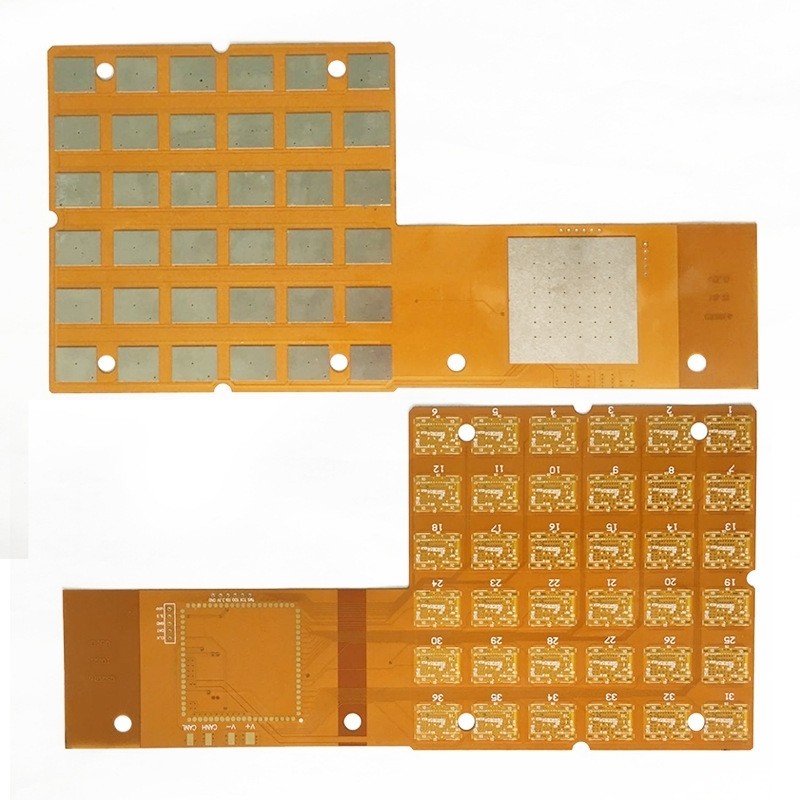

Flexible circuit board

Membrane Switch

Review

- Loading...

Please send your message to us

- *Name

- *Phone

- *Title

- *Content